Bagging

Bagging is becoming today the most popular bottle packing all around the world.

There are several reasons for opting for this kind of packaging.

AND&OR counts with a wide range of bagging machine models, to adapt to all specific needs, bags sizes, line speeds and bottles shape.

All baggers are adjustable in length and width for different bottles type and bag formats.

Automatic bagging machine

Roll of film

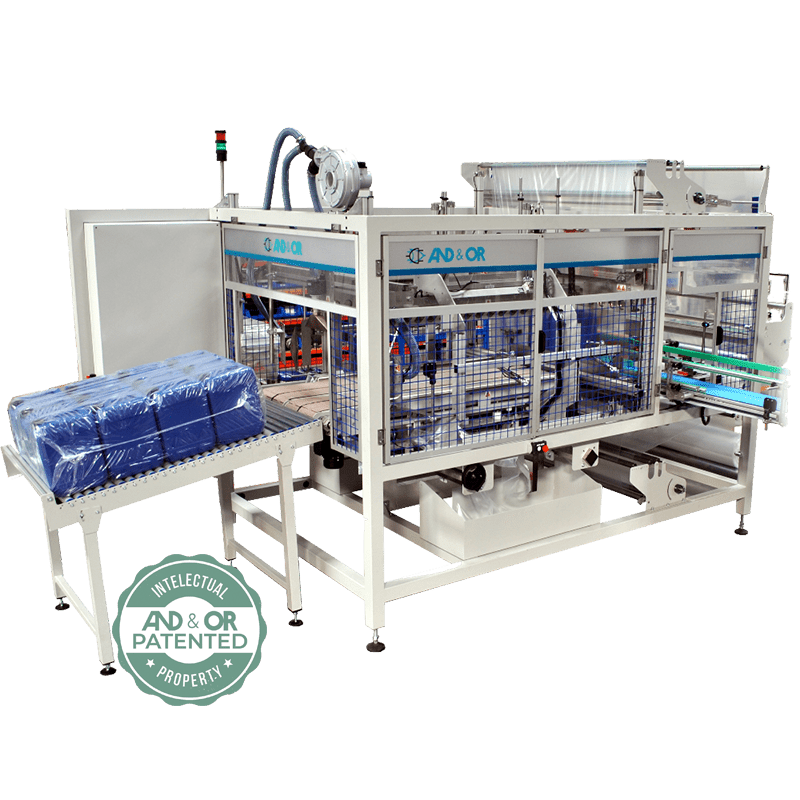

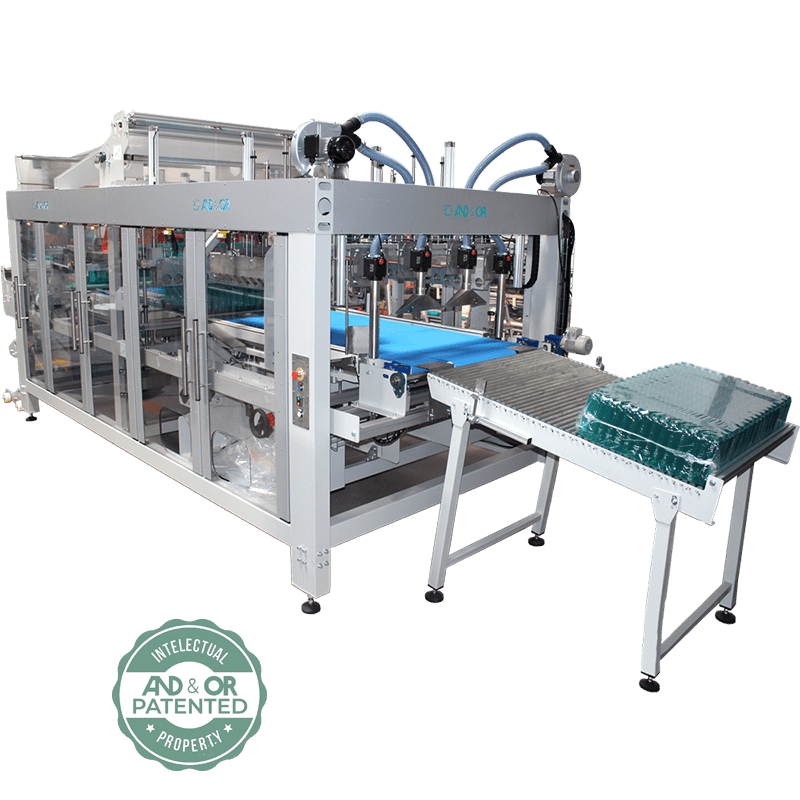

COMPACT SERIES – BMS

| From 400 to 2000 bph | Bag size (mm) |

| BMS08–A600 – Mini bagger | 500×600, 800×600, 400×600, 400×400 |

| BMS06–A1000 | 1000×600, 800×600, 800×400, 1000×400 |

| BMS12-A1000 | 1200×1000, 1200×800, 600×1000, 600×800 |

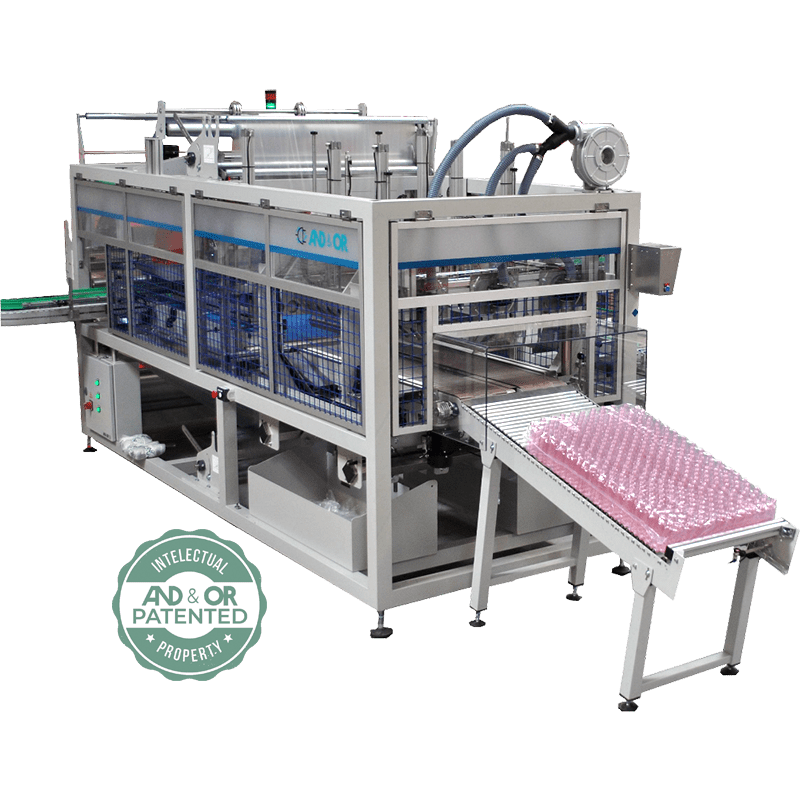

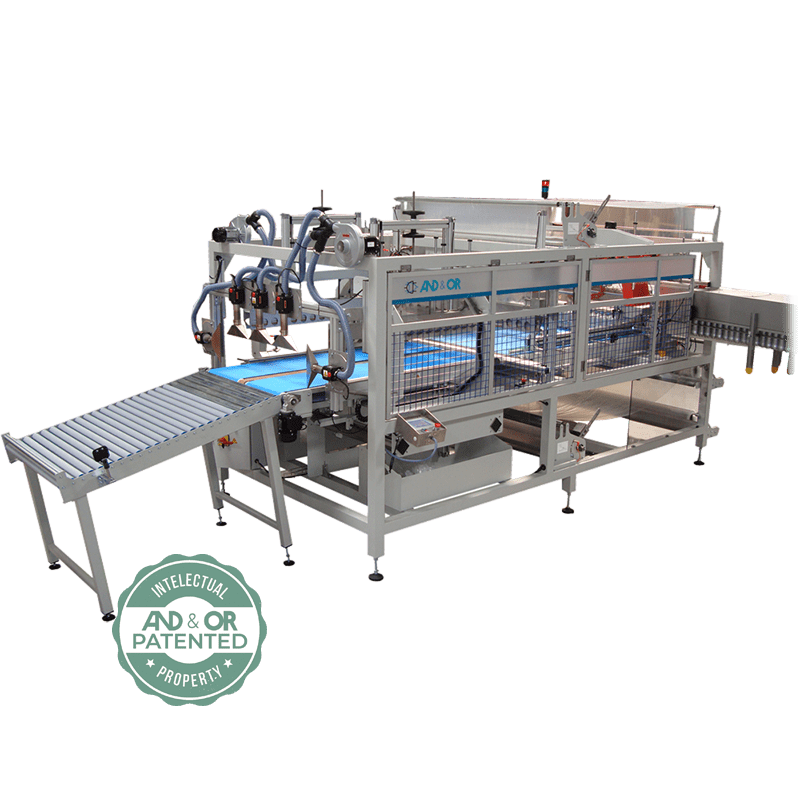

FLEXIBLE SERIES – BM

| From 2,000 to 6,000 bph | Bag size (mm) |

| BM10–A600 | 600×500, 800×600, 400×600, 400×400, 600×1000 |

| BM06–A1000 | 1000×600, 800×600, 800×400, 1000×400 |

| BM12-A1000 | 1200×1000, 1200×800, 600×1000, 600×800 |

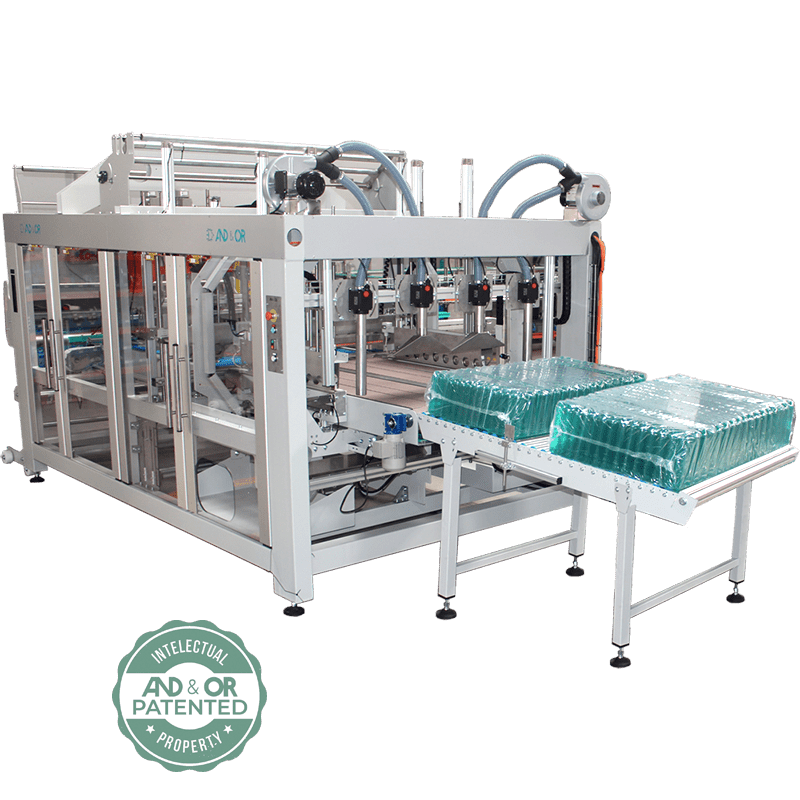

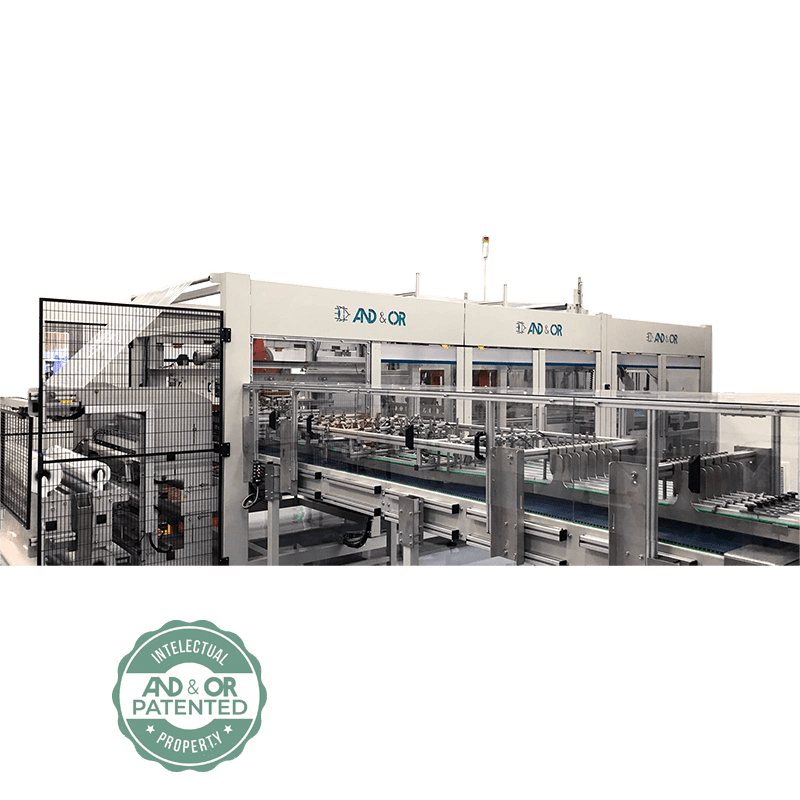

HIGH SPEED PRODUCTION

| From 6,000 to 14,000 bph | Bag size (mm) |

| BMH12-A1000 Double lane infeed |

1200×1000, 1200×800, 600×1000, 600×800 |

| BMA12-A1000 Air conveyor infeed |

1200×1000, 1200×800, 600×1000, 600×800 |

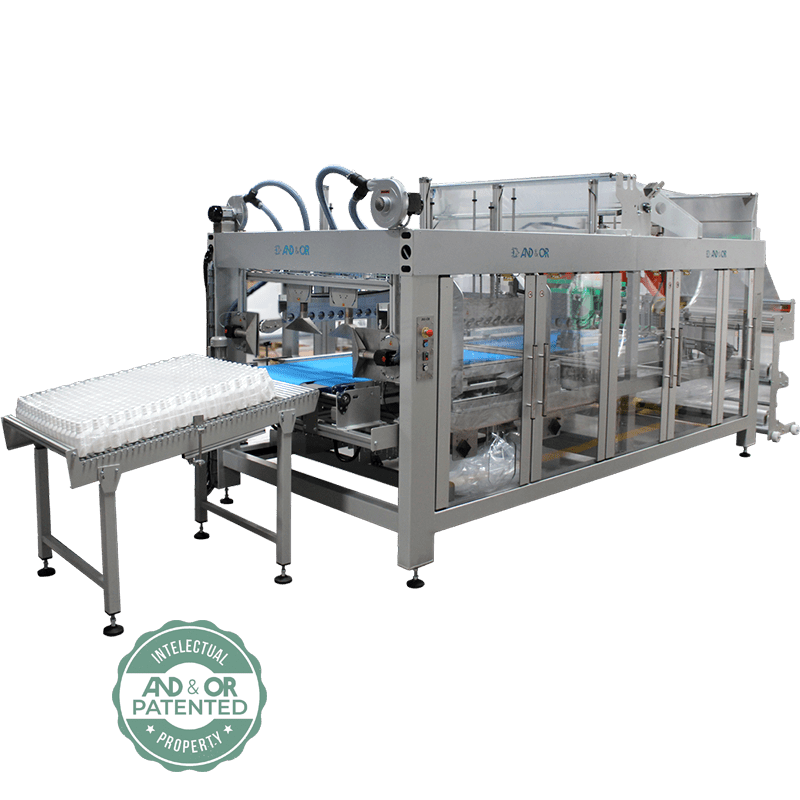

| From 15,000 to 55,000 bph | |

| BMH4-12-A1000 4 lanes infeed |

1200×1000, 1200×800, 600×1000, 600×800 |

| BMH7-12-A1000 7 lanes infeed |

1200×1000, 1200×800, 600×1000, 600×800 |

Auto adjustable bagging machine

| From 6,000 to 14,000 bph | Bag size (mm) |

| BM12-A1000-AR | Automatically adjusts being able to work with several production lines simultaneously |

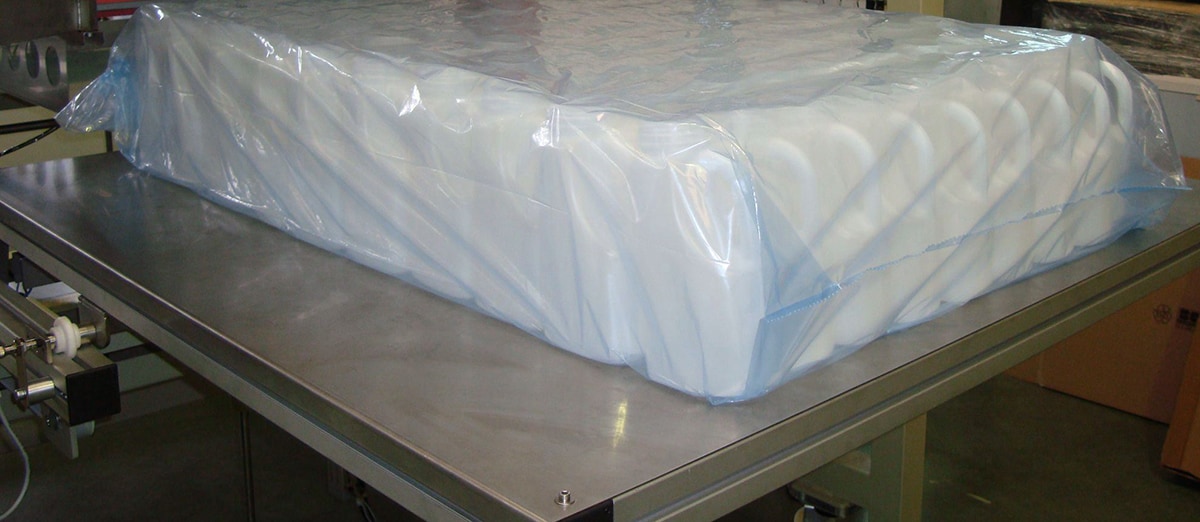

Semi automatic bagging machine – Preformed bag

ECA-BT Series

With preformed bag, all sizes.

Customized mask per bottle/bag format

Optionally, it allows the packing of bottles into cardboard trays with an open side, integrated in the same machine.

|

THE ADVANTAGES OF SHRINKING PISTOLS TOWARDS TRADITIONAL OVEN: |

|

|

AUTOMATIC SYSTEM VS. SEMI AUTOMATIC SYSTEM |

|

|

Automatic – Roll of film |

Semi automatic – Bag pre-formed |

|

Same roll of film for any bag and bottle size used in the machine. |

Every change-over requires a different size/model of preformed bag. |

AND&OR de-bagging machine (offered to the bottling industry), able to automatically de-pack and position bottles standing into the bottling line, is the perfect partner to complete the full process without risk of contamination.

Why choosing our system?

Why choosing And&Or?

Additional equipment available for all BM models:

AUTOMATING BAGGING MACHINES

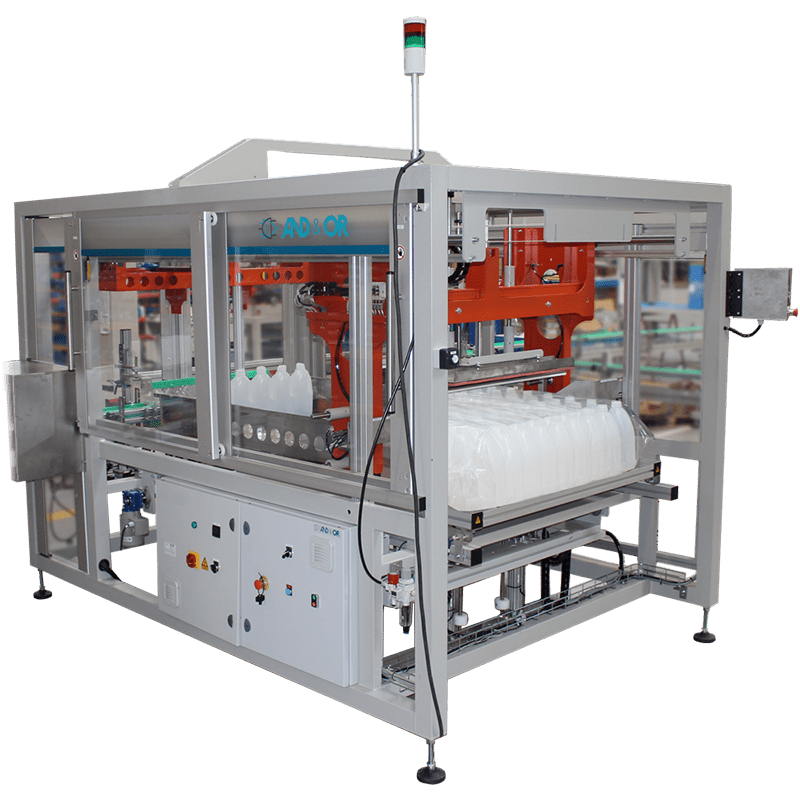

Automatic bagging machine Compact model

BMS08-A600Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Compact model.

This equipment is recommended for low cadences and steady bottles.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 500×600, 800×600, 400×600, 400×400 (mm)

*Other sizes available under request.

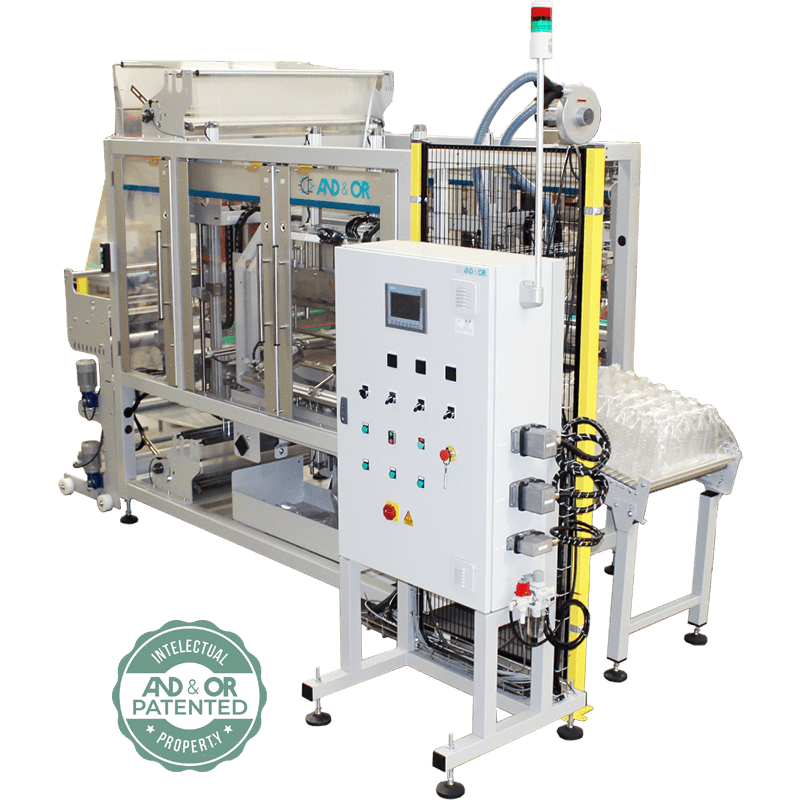

Automatic bagging machine Compact model

BMS06-A1000Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Compact model.

This equipment is recommended for low cadences and steady bottles.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 1000×600, 800×600, 800×400, 1000×400 (mm)

*Other sizes available under request.

Automatic bagging machine Compact model

BMS12-A1000Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Compact model.

This equipment is recommended for low cadences and steady bottles.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes:1200×1000, 1200×800, 600×1000, 600×800 (mm)

*Other sizes available under request.

Automatic bagging machine Flexible model

BM10–A600Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Flexible model.

This equipment is recommended for medium/high production rates and is flexible to work with different bottles formats.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 600×500, 800×600, 400×600, 600×1000 (mm)

*Other sizes available under request.

Automatic bagging machine Flexible model

BM06-A1000Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Compact model. This equipment is recommended for low cadences and steady bottles. It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes:

1000×600, 800×600, 800×400, 1000×400 (mm)

*Other sizes available under request.

Automatic bagging machine Flexible model

BM12-A1000Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Flexible model.

This equipment is recommended for medium/high production rates and is flexible to work with different bottles formats.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes:

1200×1000, 1200×800, 600×1000, 600×800 (mm)

*Other sizes available under request.

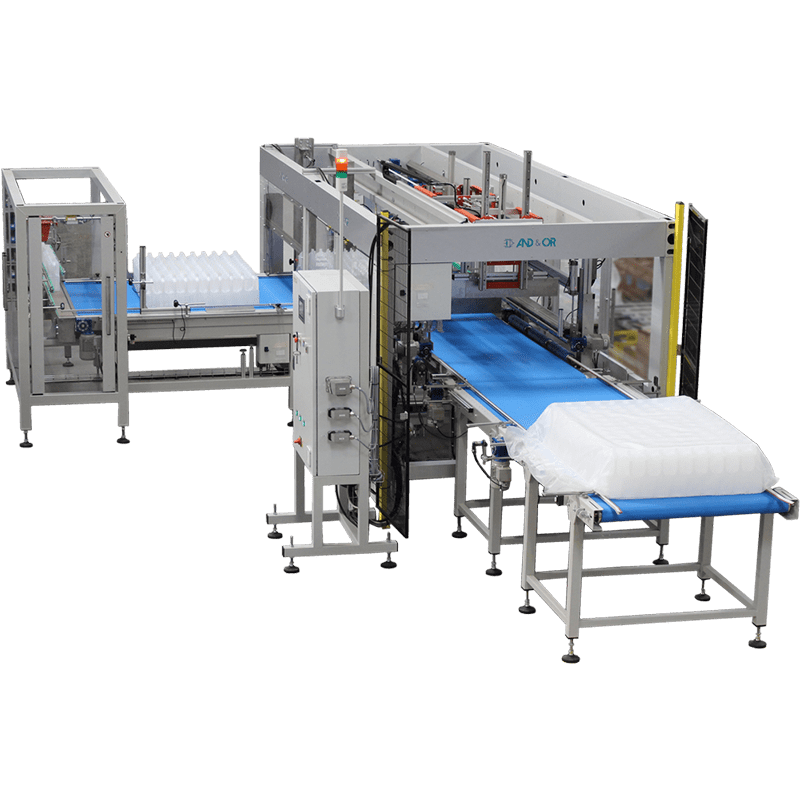

Automatic bagging machine, double lane infeed. Flexible model

BMH12-A1000Automatic bagging machine with double lane infeed, self-made bag from rolls of thermo-shrinkable film. Flexible model.

This equipment is recommended for medium/high production rates and is flexible to work with different bottles formats.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 1200×1000, 1200×800, 600×1000, 600×800 (mm)

*Other sizes available under request.

Automatic bagging machine, air conveyor infeed. Flexible model

BMA12-A1000Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Flexible model.

This equipment is recommended for high production rates when bottle transport is made by air conveyors. It is flexible to work with different bottles formats (designed for bottles with petaloid base).

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes:1200×1000, 1200×800, 600×1000, 600×800 (mm)

*Other sizes available under request.

Automatic bagging machine, 4 lanes infeed. Flexible model

BMH4-12-A1000Automatic bagging machine with 4 lanes infeed, self-made bag from rolls of thermo-shrinkable film. Flexible model.

This equipment is recommended for medium/high production rates and is flexible to work with different bottles formats.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 1200×1000, 1200×800, 600×1000, 600×800 (mm)

*Other sizes available under request.

Automatic bagging machine, 7 lanes infeed. Flexible model

BMH7-12-A1000Automatic bagging machine with 7 lanes infeed, self-made bag from rolls of thermo-shrinkable film. Flexible model.

This equipment is recommended for medium/high production rates and is flexible to work with different bottles formats.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 1200×1000, 1200×800, 600×1000, 600×800 (mm)

*Other sizes available under request.

Semi-automatic bagging machine for preformed bag

ECA-BTSemi-automatic bagging machine for preformed bag with an open side.

It is usually installed after the blower and the leak tester.

Operator intervention is needed to clear the formed bag and to place the new empty one. Each bag size requires a customized metallic tray, guaranteeing the best possible compactness.

Maximum production rate: depending on bottle/bag format.

Optionally, it allows the packing of bottles into cardboard trays with an open side, integrated in the same machine.

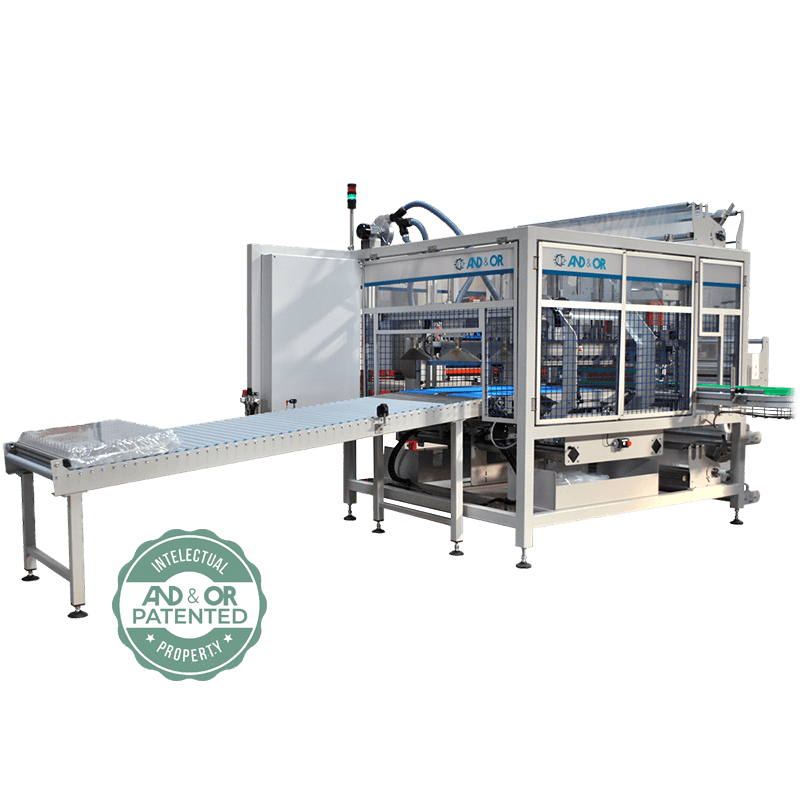

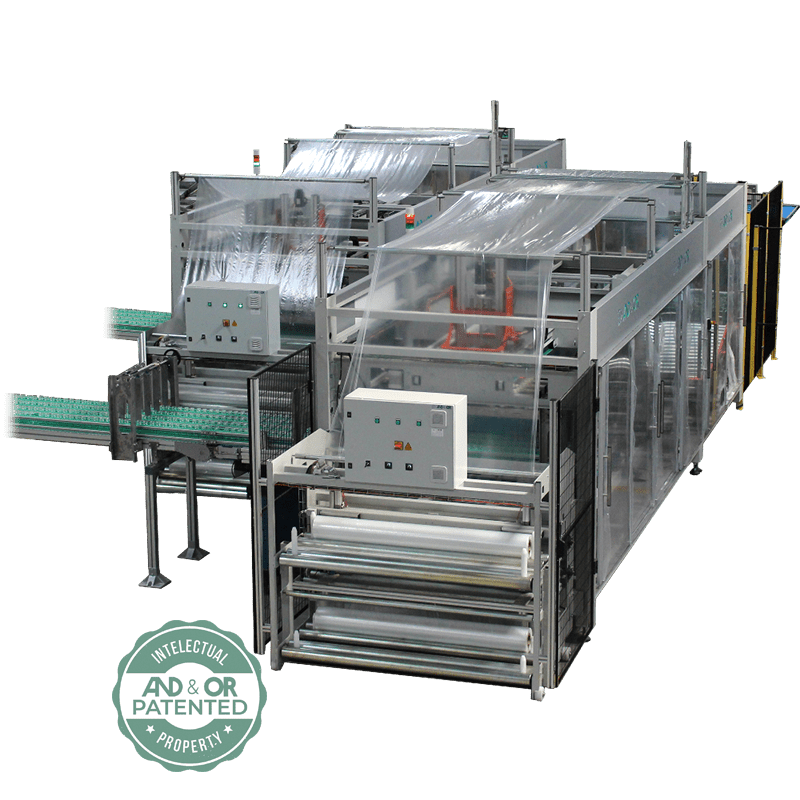

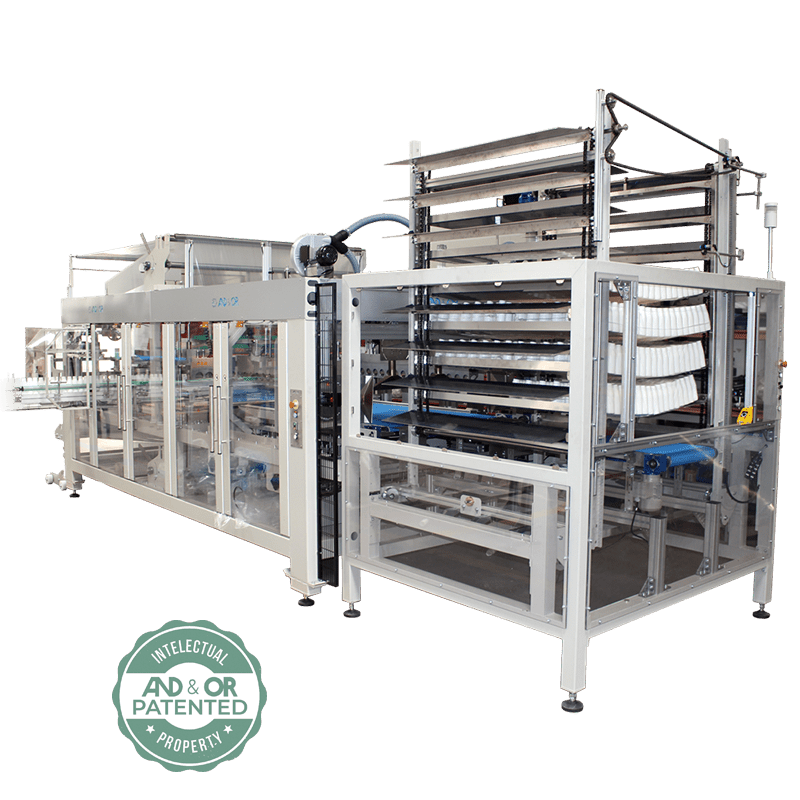

Bagging machine with bag stacker

BM+STACKBM+STACK

Bagging machine with bag stacker.

Bagging machine with motorized conveyor for bags storage.

Number of bags depending on bottle height.

Additional system compatible with different bagging models.

Downloadable content

The content is restricted, in order to have access it is necessary to register