Handle applicators

AND&OR is nowadays the world leader in the manufacture and marketing of plastic handle application machines for PET or HDPE bottles. Through its long experience and the widest range in the market, AND&OR provides solutions for all its customers production needs.

The AND&OR handle applicators systems allow the insertion of neck handles, lateral handles, umbrella handles, and handles buckets for low, medium, and high production rates.

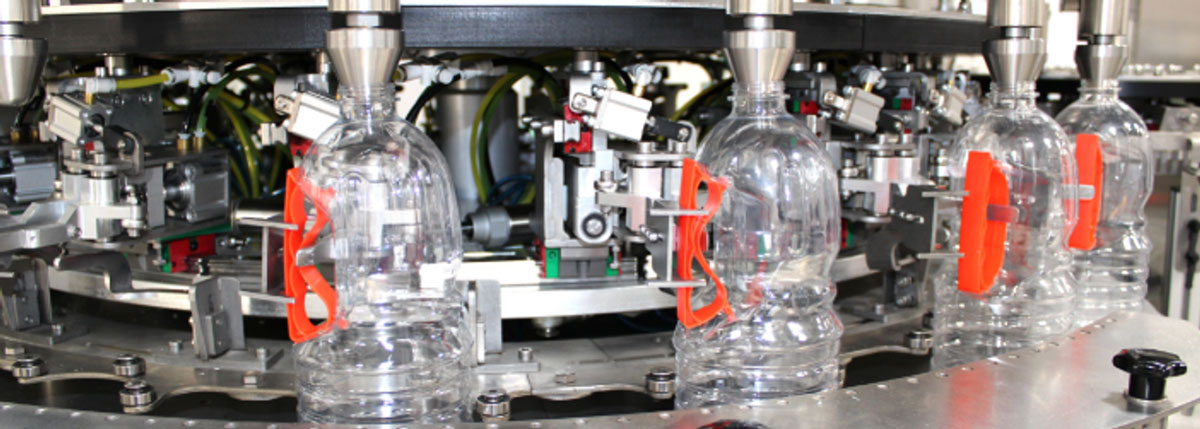

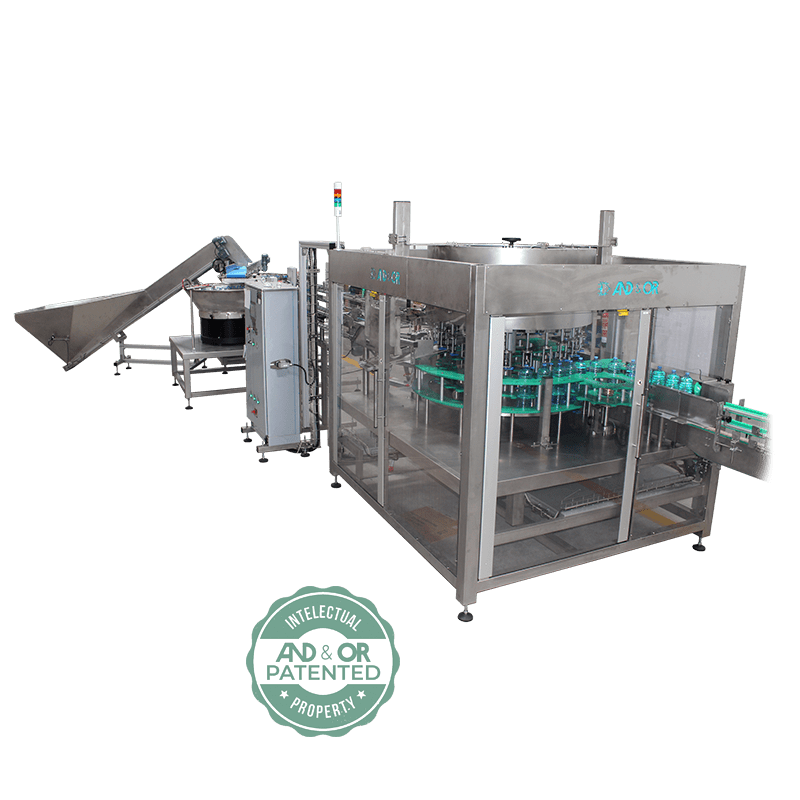

Neck handle applicators

(PET or HDPE bottles from 1.5L to 20L)

- Alternative linear systems (pick & place): 1,200 – 2,400 bottles per hour (bph)

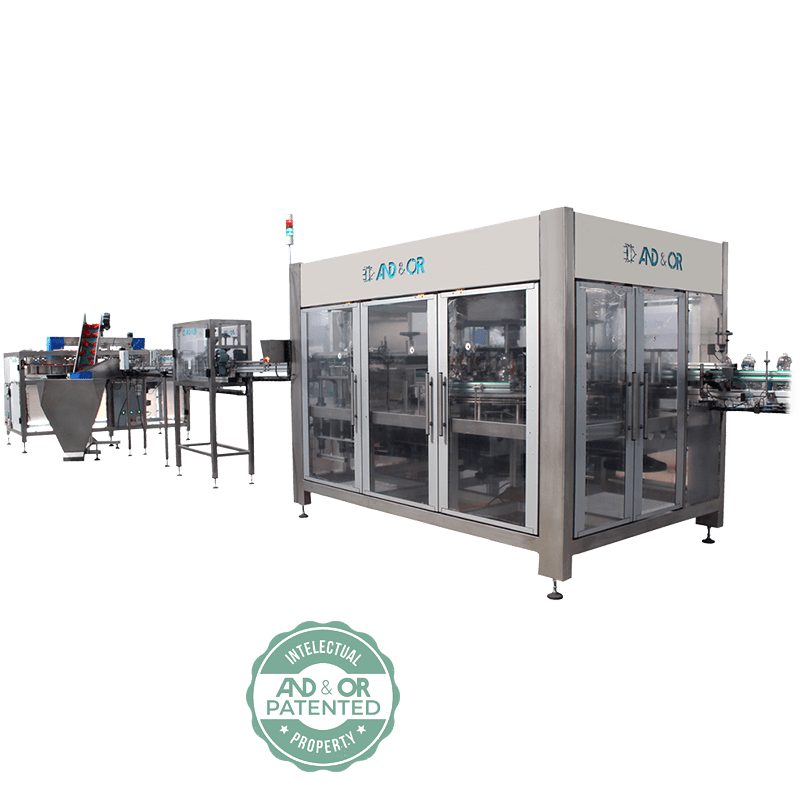

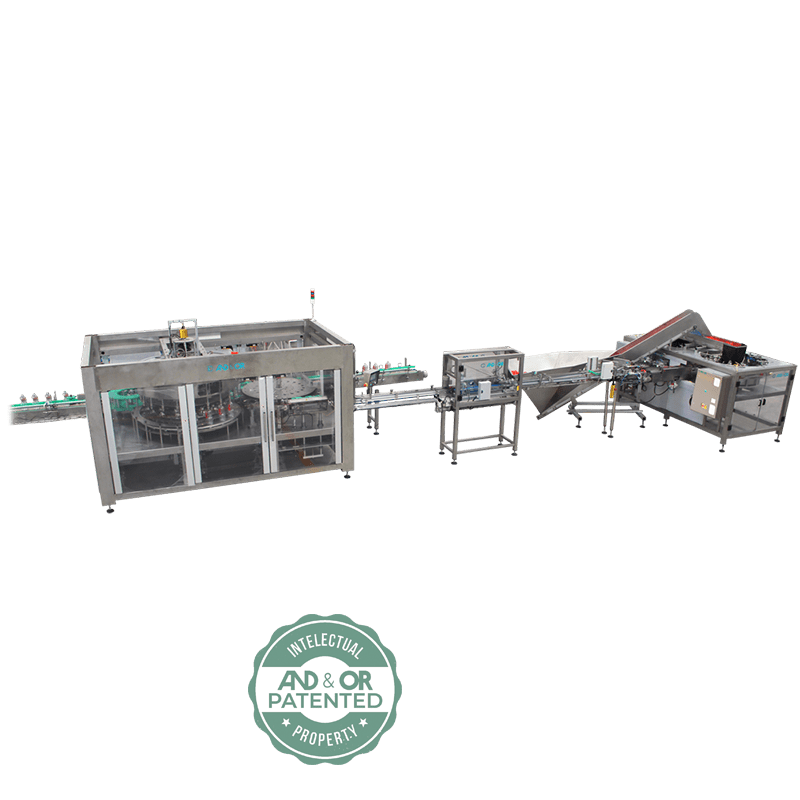

- Continuous linear systems: 4,000 – 10,000 bph

- Rotary systems: 10,000 – 24,000 bph

They are installed in both blow molding and bottling lines (usually after the filling and capping processes).

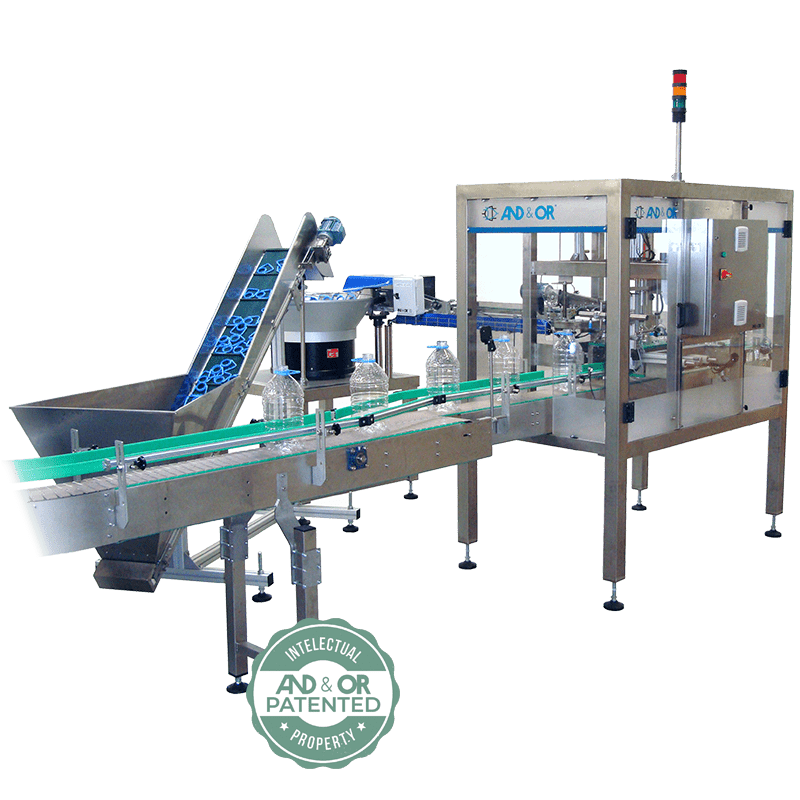

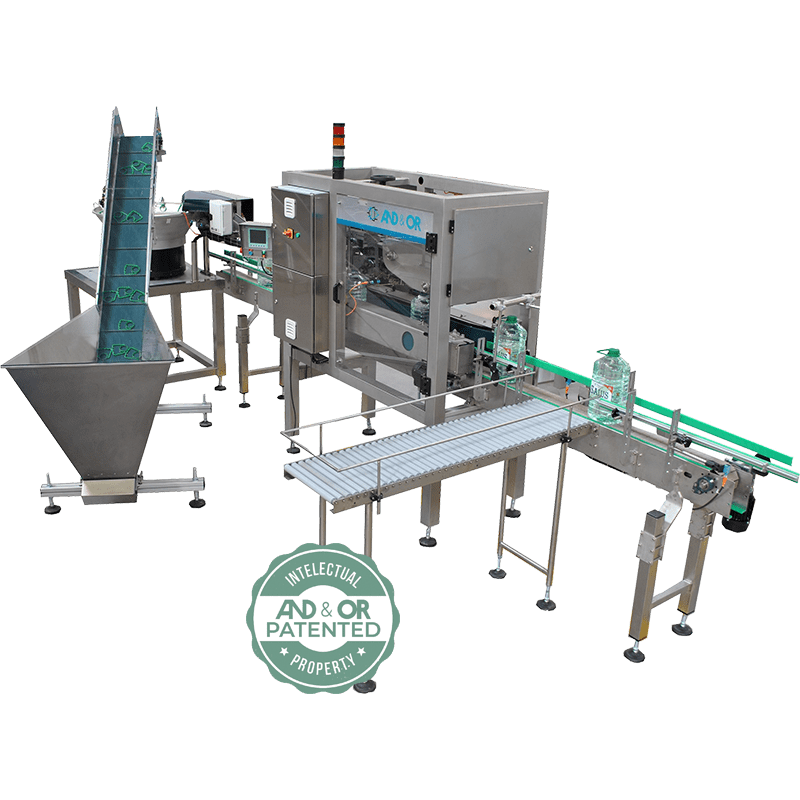

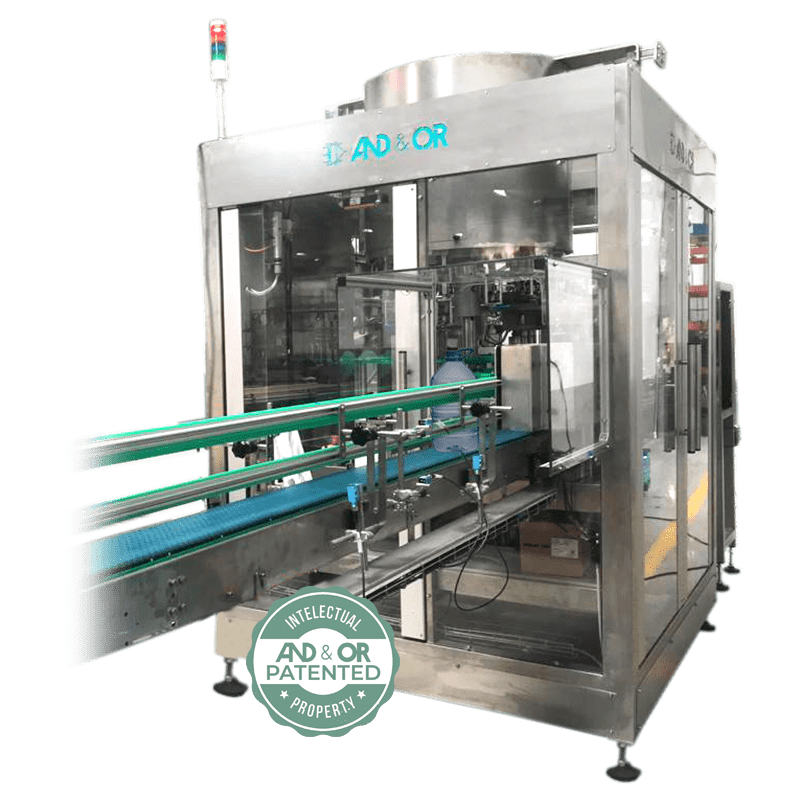

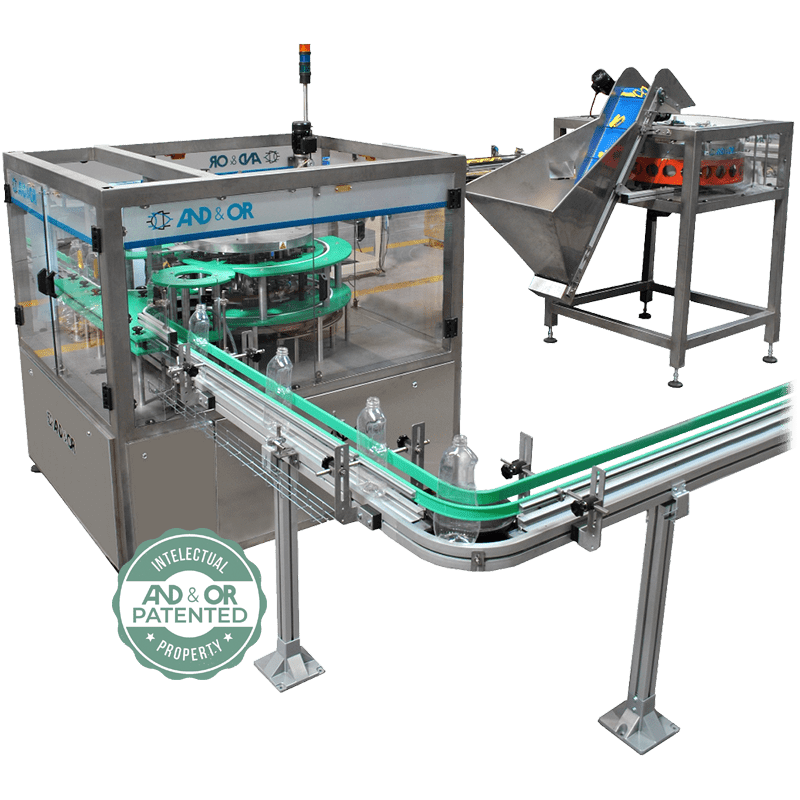

Lateral handle applicators

(PET bottles from 1.5L to 5L)

The lateral handle applicators allow the automatic insertion of a flexible plastic handle in the lateral gap of a PET bottle.

It is appropriate to be installed in both blow molding and filling lines (on existing conveyor, before filling process).

It allows using PET bottles for some beverages and liquid products which need an easy holding for pouring. It replaces the traditional HDPE systems with handle, reaching higer speeds and cost savings.

- Linear systems: 800 bottles per hour (bph)

- Rotary systems: 2,000 – 15,000 bph

Optionally, these systems can be integrated in the machine:

- leak testing equipment

- positioning device

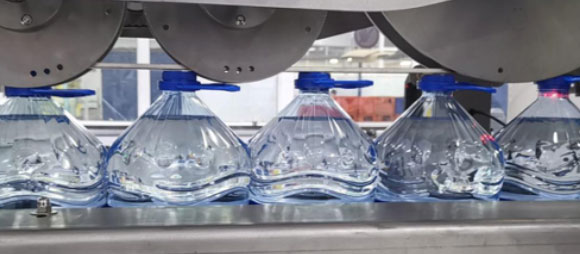

Umbrella handle applicators

(PET bottles from 1.5 to 5L)

| Up to… Bottles Per Hour (BPH) | 1000 | 2000 | 4000 | 6000 | 12000 | 24000 |

|---|---|---|---|---|---|---|

| Reference | SIAP1000 | SIAP2000 | SIAP4000 | SIAP8000 | SIAP12000 | SIAP24000 |

| Up to… Bottles Per Hour (BPH) | Reference |

|---|---|

| 1000 | SIAP1000 |

| 2000 | SIAP2000 |

| 4000 | SIAP4000 |

| 8000 | SIAP8000 |

| 12000 | SIAP12000 |

| 24000 | SIAP24000 |

Handle applicators on buckets

Our handle applicator system on buckets performs the insertion of handles on PET or PE buckets. It is a fully automatic system that allows tumble or pre oriented handles feeding, according to line characteristics.

| Reference | 50A1ASA-FLAT |

|---|

Why choosing our system?

Why choosing And&Or?

HANDLE APPLICATOR MACHINES

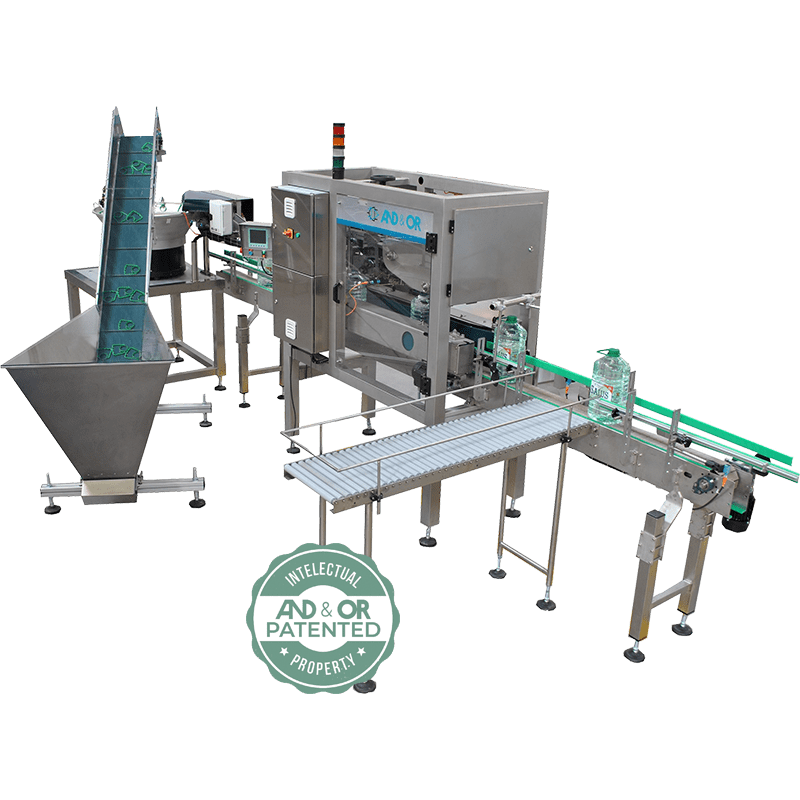

Neck handle applicator. Production rate: 1,200 BPH

SIA1000Handle applicator SIA1000 performs the orientation and insertion of polyethylene handles (PE) on PET bottles (from 2 to 20 liters). It is based on a machine with alternative movements (pick and place).

It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

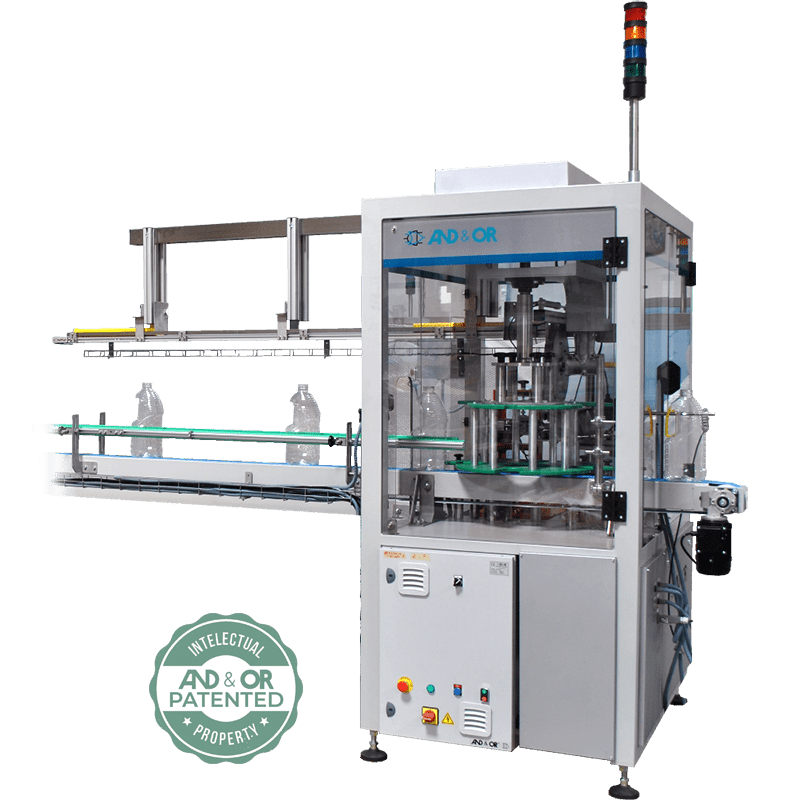

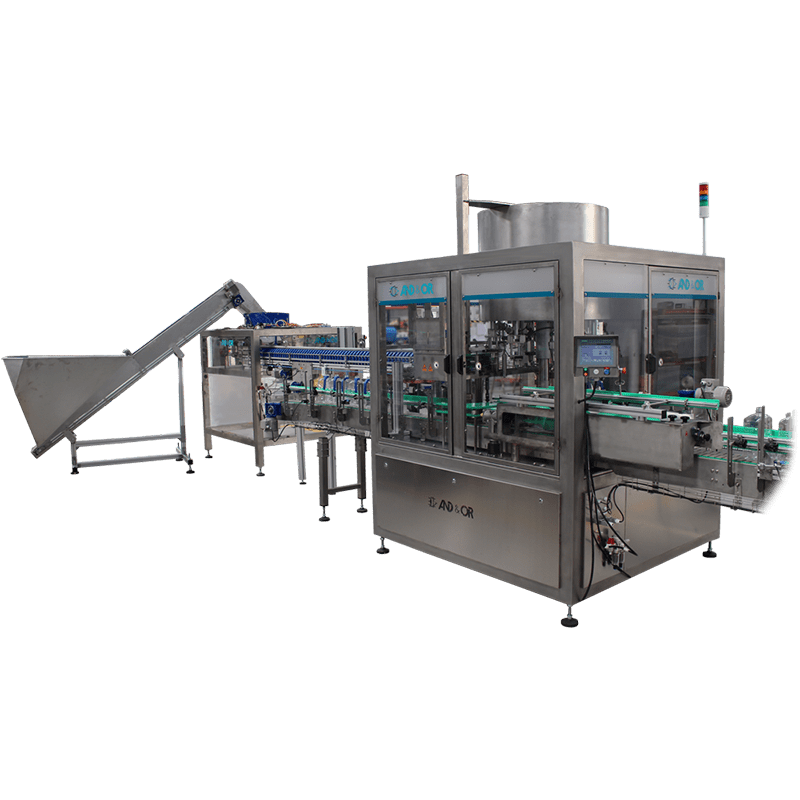

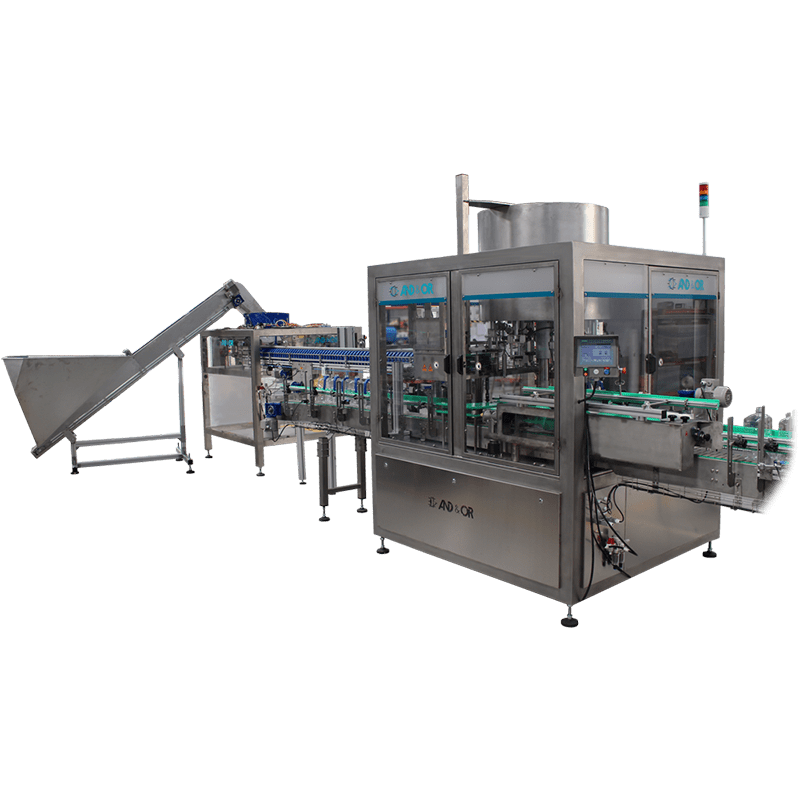

Neck handle applicator. Production rate: 2,400 BPH

SIA2000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Neck handle applicator. Production rate: 4,000 BPH

SIA3000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Neck handle applicator. Production rate: 6,000 BPH

SIA5000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Neck handle applicator. Production rate: 8,000 BPH

SIA8000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Maximum production rate: 8,000 BPH – Bottle volume ≥ 5L, Neck ø 38/48mm

Maximum production rate: 10,000 BPH – Bottle volume ≥ 1.5-3L, Neck ø 28mm

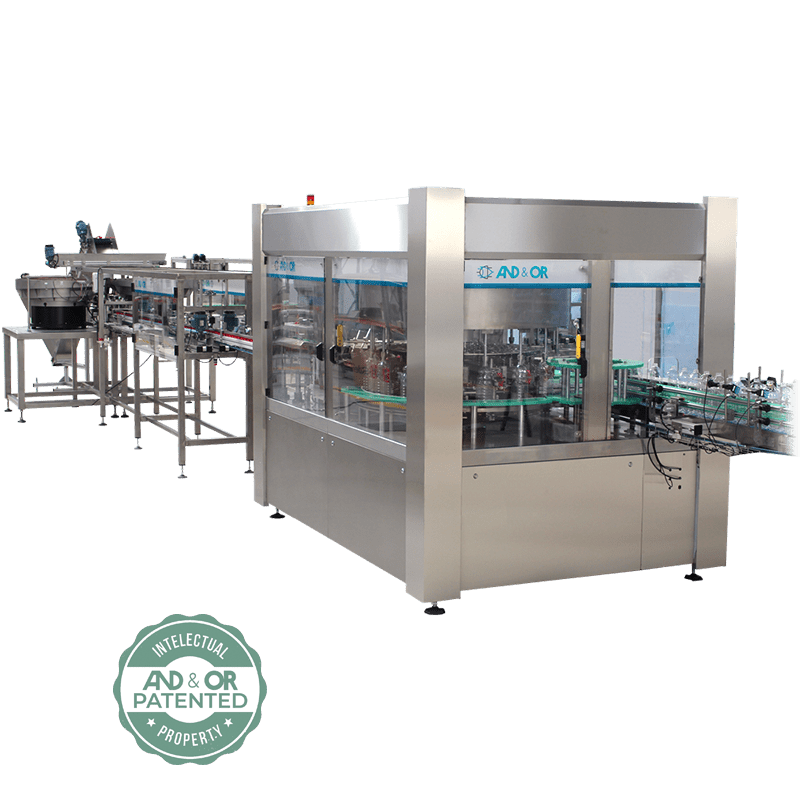

Neck handle applicator. Production rate: 12,000 BPH

SIA12000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Neck handle applicator. Production rate: 16,000 BPH

SIA16000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Neck handle applicator. Production rate: 24,000 BPH

SIA24000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

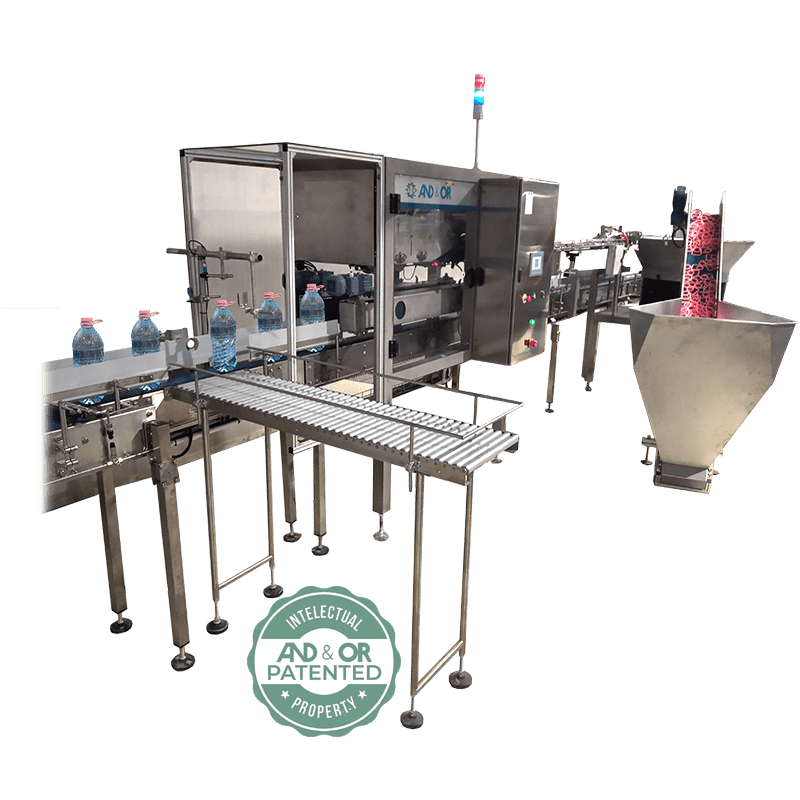

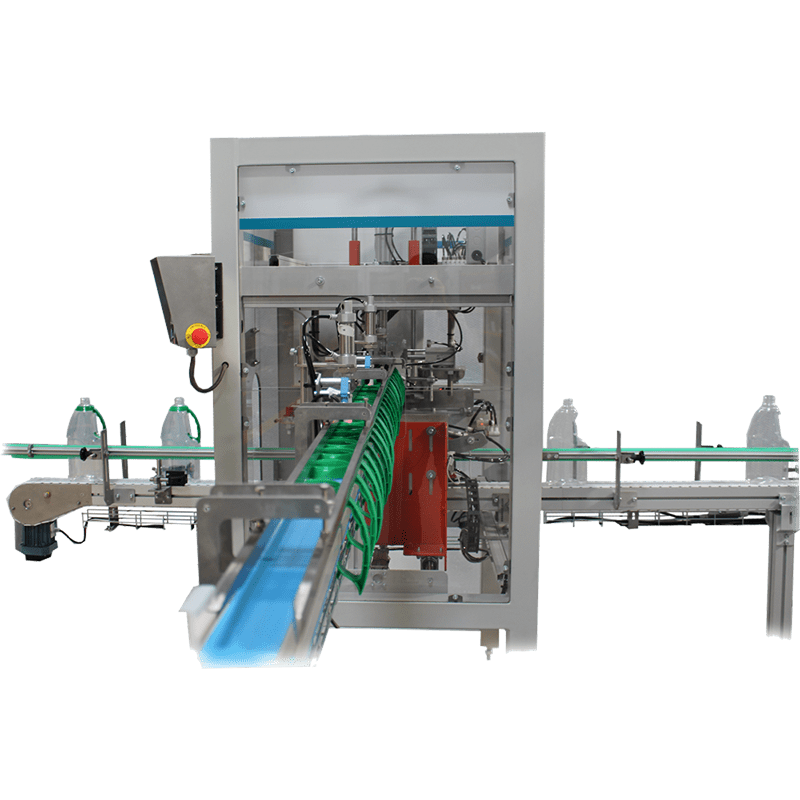

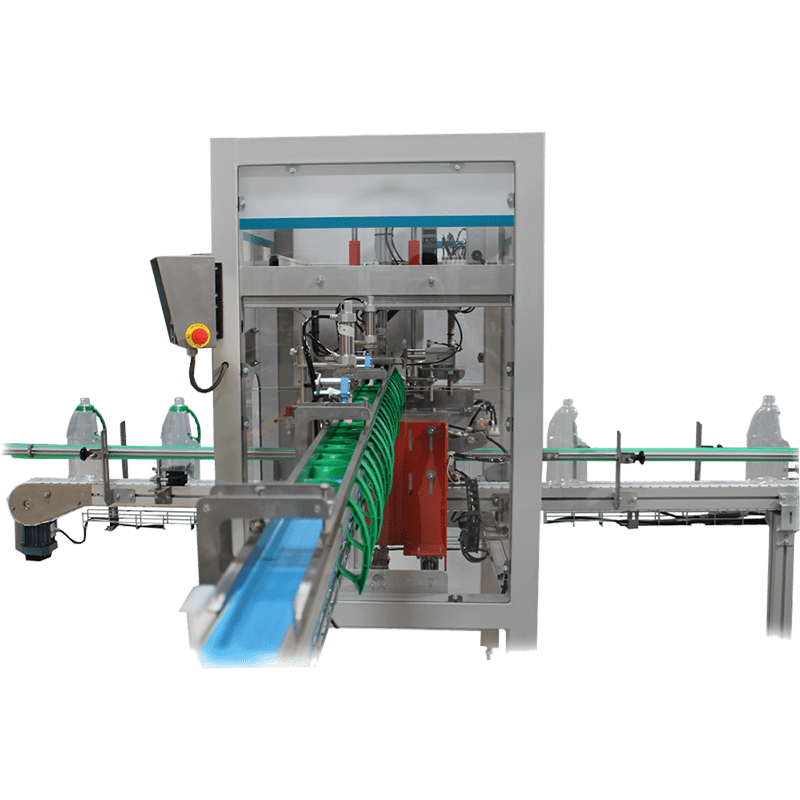

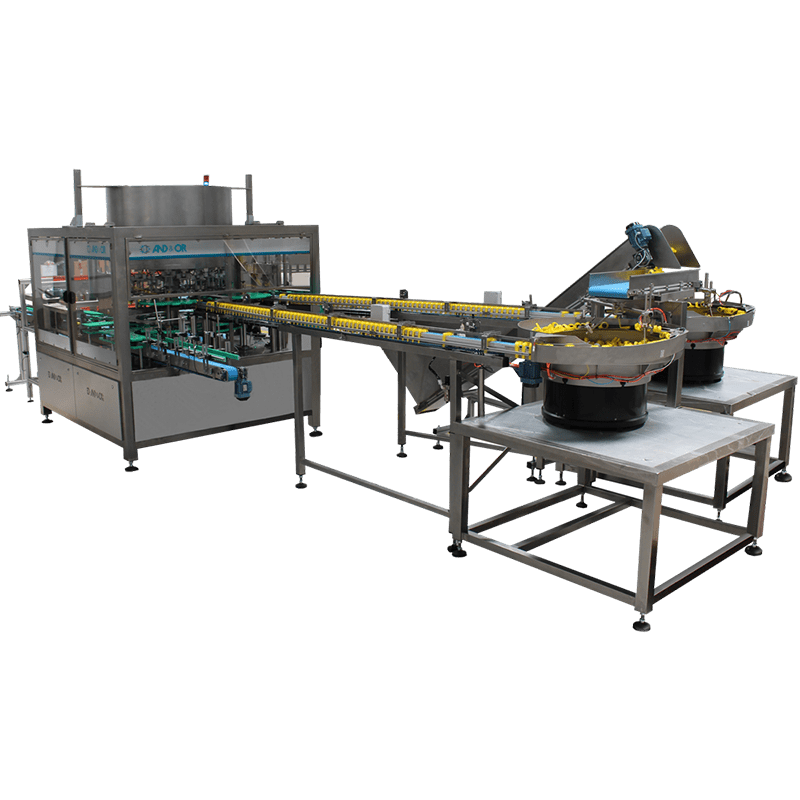

Lateral handle applicator. Production rate: 1,000 BPH

SIAL1000 / SIALG1000

Lateral handle applicator. Production rate: 3,000 BPH

SIAL3000 / SIALG3000

Lateral handle applicator. Production rate: 6,000 BPH

SIAL 6000/SIALG 6000This system allows using PET bottles for some products when an easy pouring process is required.

Lateral handle applicator. Production rate: 8,000 BPH

SIAL8000 / SIALG8000This system allows using PET bottles for some products when an easy pouring process is required.

Lateral handle applicator. Production rate: 12,500 BPH

SIAL12000 / SIALG12000This system allows using PET bottles for some products when an easy pouring process is required.

Lateral handle applicator. Production rate: 15,000 BPH

SIAL15000/SIALG15000Handle applicator SIAL15000 / SIALG15000 performs the insertion of (PE) lateral handles on PET bottles (from 2 up to 5 liters). It is based on a rotary continuous system and is appropriate to be installed in the existing packaging line, on an existing conveyor and before the filling process.

This system allows using PET bottles for some products when an easy pouring process is required.

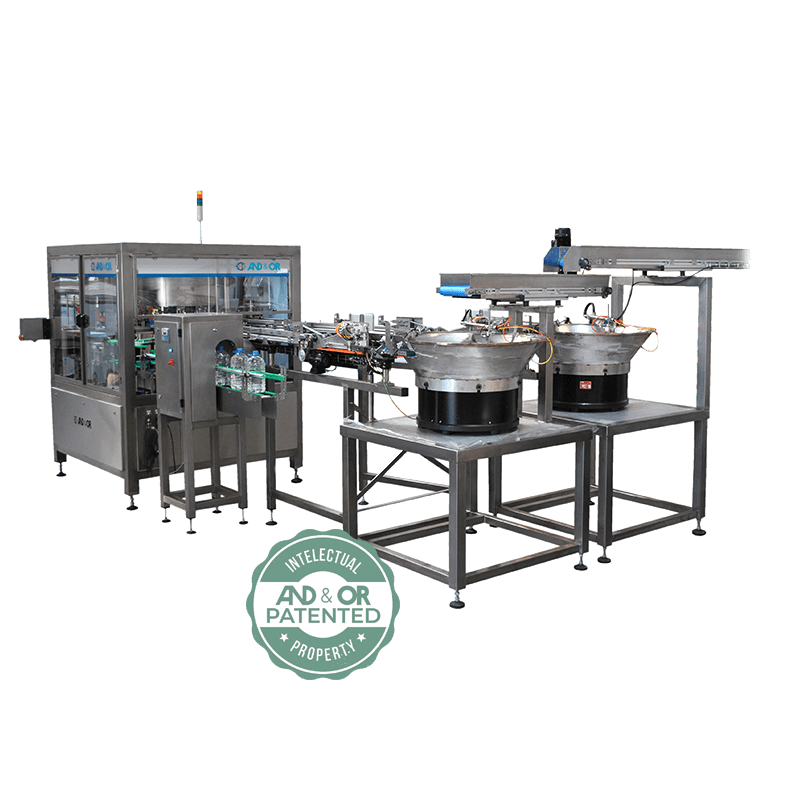

Umbrella handle applicator. Production rate: 1,000 BPH

SIAP1000Handle applicator SIAP 1000 performs the orientation and insertion of polyethylene umbrella handles (PE) on PET bottles (from 2 to 3 liters). It is based on a rotary machine with continuous movement.

It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Umbrella handle applicator. Production rate: 2,000 BPH

SIAP2000Handle applicator SIAP 2000 performs the orientation and insertion of polyethylene umbrella handles (PE) on PET bottles (from 2 to 3 liters). It is based on a rotary machine with continuous movement.

It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Umbrella handle applicator. Production rate: 4,000 BPH

SIAP4000Handle applicator SIAP 4000 performs the orientation and insertion of polyethylene umbrella handles (PE) on PET bottles (from 2 to 3 liters). It is based on a rotary machine with continuous movement.

It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Umbrella handle applicator. Production rate: 8,000 BPH

SIAP8000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Umbrella handle applicator. Production rate: 12,000 BPH

SIAP12000El equipo automático SIAP 12000 realiza la inserción de asas de polietileno (PE) tipo paraguas en garrafas PET vacías o llenas, de 2 a 3 litros. Basada en una máquina rotativa de movimiento continuo, es un sistema adecuado para colocar bien en línea de soplado, a la salida de la sopladora, o línea de envasado, sobre el transportador existente y después del taponado.

Umbrella handle applicator. Production rate: 24,000 BPH

SIAP24000It is appropriate to be installed either after the blower in blow molding lines or after the filler, within the filling line, over an existing conveyor and after the capping system.

Downloadable content

The content is restricted, in order to have access it is necessary to register