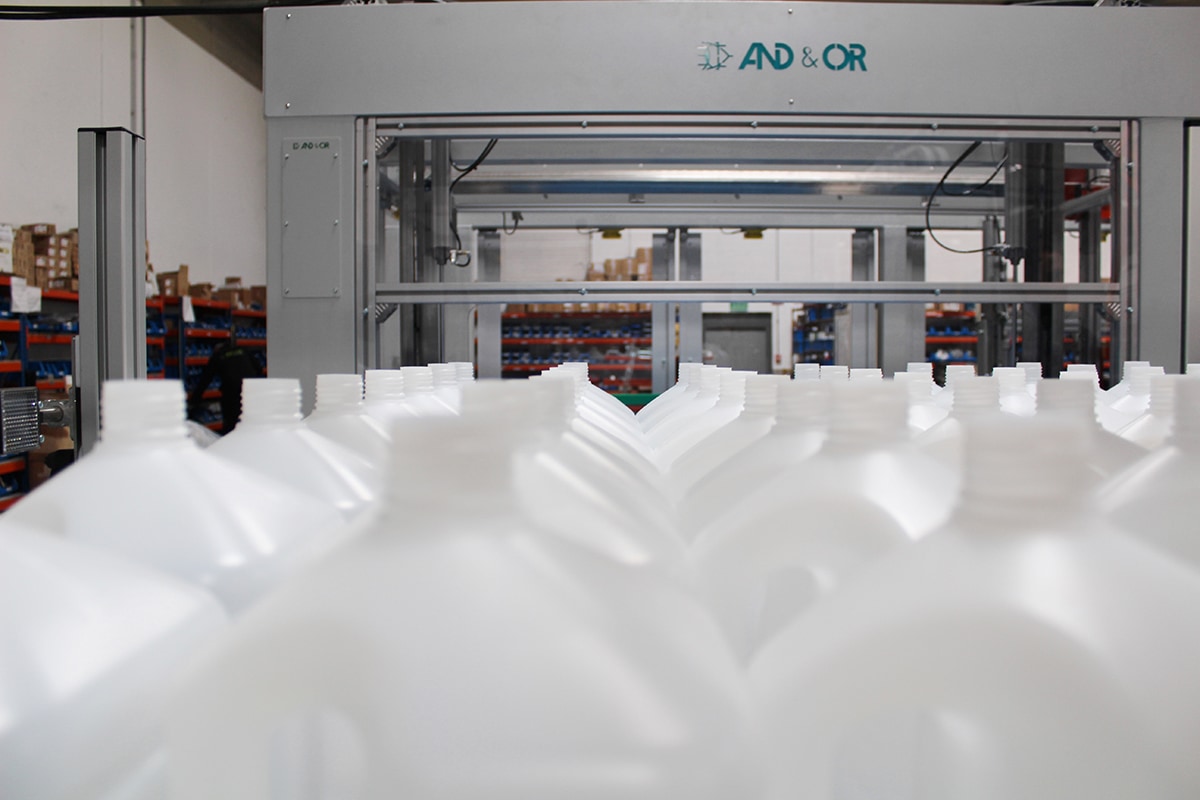

Automatic depalletizers and debaggers

Depalletizers

AND&OR offers machinery for the bottles depalletizing for plastic (PET and PE), metal (cans) and glass.

These systems are modular units that allow a degree of automation in accordance with customer specific needs: input conveyors for full pallets, empty pallet warehouse, automatic cardboard tray/interlayer/film removal, etc.

The output table and line-up conveyors are defined according to the product to line-up (PET, HDPE, glass, cans, etc.), bottle shape (oval, square o round) and filling line speed.

Debaggers

Towards the traditional tray packing, bagging is becoming today a more and more popular way of bottle packing. Bagging avoids bottle’s contamination from contact with cardboard trays or any other.

To guarantee the hygiene in the products it is especially important in the food, pharmaceutical or cosmetic industries.

AND&OR manufactures automatic baggers especially designed to allow an easy and automatic debag by an AND&OR debagger. Closing the cycle, AND&OR tries to make things easy to both blow molding and bottling industries.

AND&OR offers automatic bagging and debagging systems for glass and PET/HDPE bottles, avoiding contamination of products and any possible human manipulation of the bottles from the blowing to the filling.

Extra related systems can be added depending on automation level required: bags depalletizer robot, interlayer removal, pallet conveyors, interlayer warehouse, empty pallet warehouse, etc.

Bagging / Debagging

Pal / Depal

Concept

ADVANTAGES

- Optimization of material costs.

- Lower investment facing silos and positioners.

- Lower compressed air consumption.

- The required warehouse space is much smaller than when using silos (half space required to stock a same number of bottles).

- If bagged, product hygiene is guaranteed, since it is hermetically sealed during the storage period.

- There are fewer line stops, as the deformed bottles percentage is almost nonexistent. This increases the efficiency.

Why choosing our system?

Why choosing And&Or?

DEPALLETIZING & DEBAGGING MACHINES

Automatic bottles depalletizer

RDZ-CPEAutomatic depalletizer of plastic bottles to hopper/positioner.

It includes elevator platform and pallet centering unit as well as a pallet input conveyor to allow some accumulation buffer (customized depending on client’s requirements).

This equipment works with palletized bottles in inverted trays or sheets.

Sheets/trays/pallets are automatically extracted and stacked nearby.

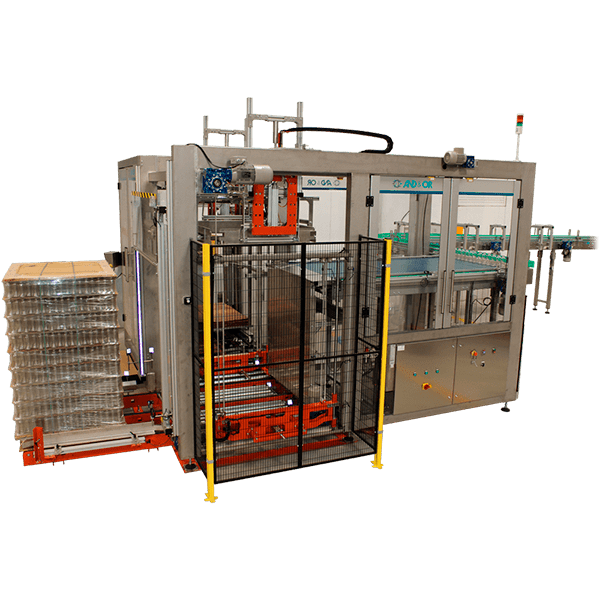

Automatic bottles depalletizer Gantry type, fixed pallet

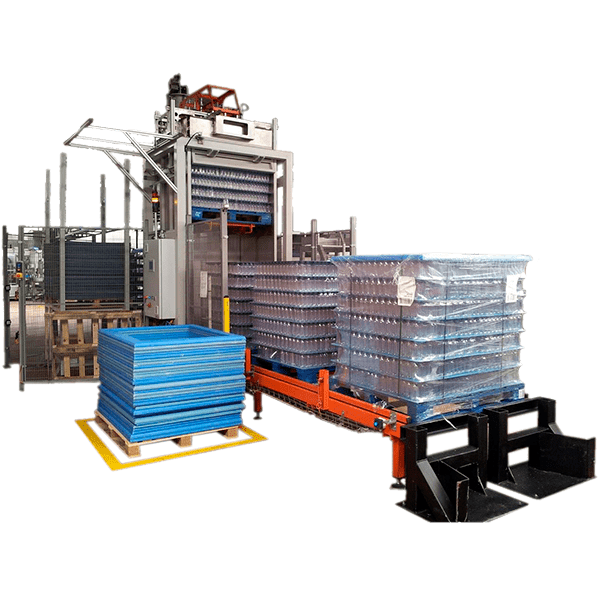

DEPALAutomatic bottles depalletizer (plastic or glass) and subsequent launch to filling line.

Stability of bottles throughout the depalletizing process is guaranteed, thanks to the holding frame between pallet and launching table, using an intermediate motorized platform.

Automatic bottles depalletizer with structure, fixed pallet

DEPALAutomatic bottles depalletizer (plastic or glass) and subsequent launch to filling line.

It includes pallet centering unit, frame with vertical and horizontal movement for layer fastening and sliding from pallet to motorized platform (adjustable in height for pallets up to 2.8 meters) and from motorized platform to launching table to packaging line.

Optionally, it can include a pallet input conveyor as well, to allow some accumulation buffer in the input, an automatic pallet warehouse, automatic carton/plastic extraction and bottle alignment table to packaging line.

This equipment works with palletized bottles in inverted trays or sheets.

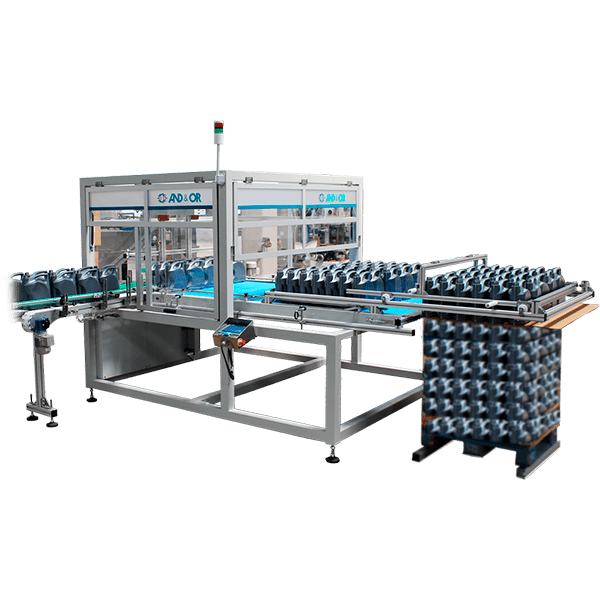

Automatic bottles depalletizer pallet on rising platform

DMAM-EAutomatic depalletizer of bottles (plastic, metallic or glass) and subsequent launch to filling line (pallets up to 1.5 meters).

This equipment works with palletized bottles in inverted trays or sheets. The maximum height of the pallet is determined by the height of the input conveyor of the filling line.

It is formed by a motorized pallet elevation platform and an automatic carriage with a frame which slides layers from the pallet to the launching table. Depending on the line requirements, there are different bottles alignment systems from table to filling line input conveyor.

Optionally, it can include a system to retrieve sheet/tray automatically and its storage nearby. Full pallet conveyor can also be integrated at the inlet of the depalletizer, as well as a storage for empty pallet at the outlet.

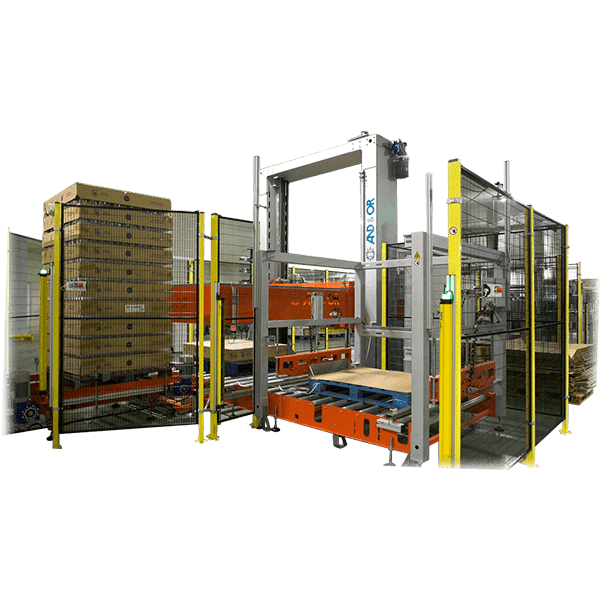

Automatic bottles depalletizer Pick&Place columnar gripper

RDZ-DMAMAutomatic depalletizer of bottles (plastic or metallic) and subsequent launch to filling line (pallets up to 2.7 meters).

This equipment works with palletized bottles in inverted trays or sheets.

This system depalletizes bottles automatically to the filling line and is composed by a RDZ robot that picks bottle layers and a DMAM table that allows accumulating and launching of bottles to the filling line. Depending on the line requirements, there are different bottles alignment systems. Robot extract sheets/trays automatically and it storages them in an annexed warehouse.

Optionally, full pallet conveyor can also be integrated at the inlet of the depalletizer, as well as a buffer for empty pallet at the outlet.

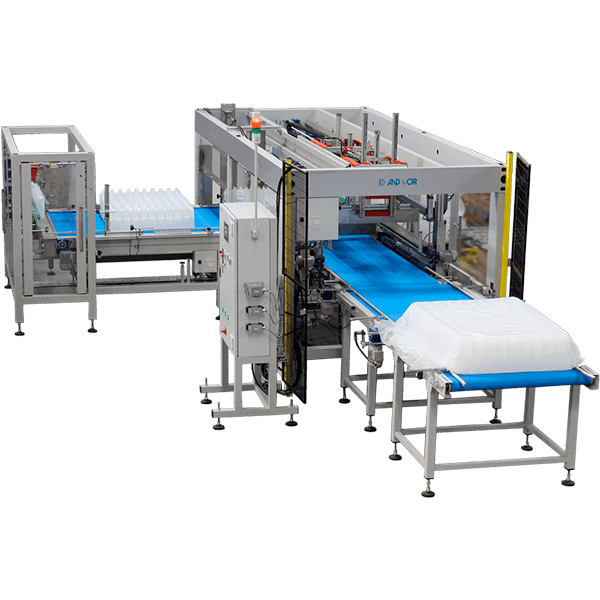

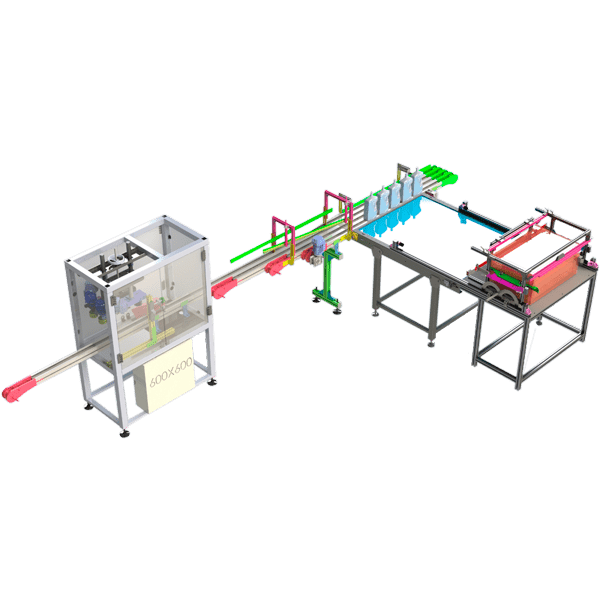

Depalletizing and debagging of plastic bottles

DBM+RDZAutomatic debagger for plastic bottles. AND&OR manufactures automatic baggers especially designed to allow an easy and automatic debag by an AND&OR’s debagger. Having closed the circle, AND&OR tries to make things easier to both, the blow molding and bottling industries.

Debagger DBM-CL does not disarrange the bottles when opening the bag, thus, bottles can be positioned into the bottling line without an unscrambler. There are different models depending on the bottle size and shape, line speed, bags size, etc.

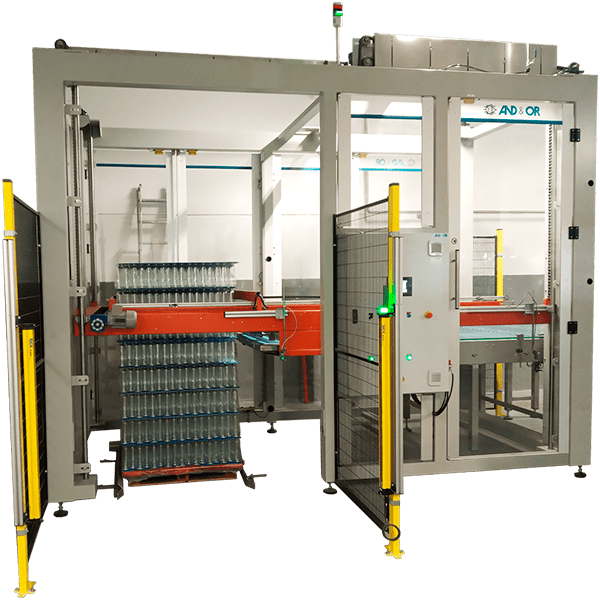

Automatic plastic bottles debagger

DBM-CLAutomatic debagger for plastic bottles. AND&OR manufactures automatic baggers especially designed to allow an easy and automatic debag by an AND&OR’s debagger. Having closed the circle, AND&OR tries to make things easier to both, the blow molding and bottling industries.

Debagger DBM-CL does not disarrange the bottles when opening the bag, thus, bottles can be positioned into the bottling line without an unscrambler. There are different models depending on the bottle size and shape, line speed, bags size, etc.

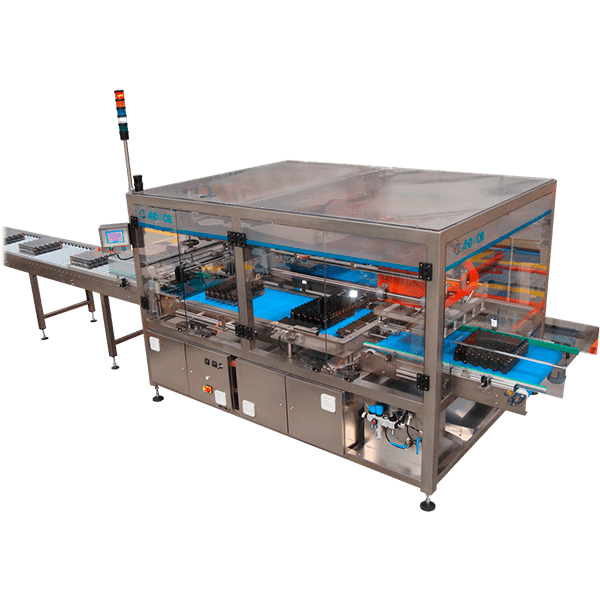

Automatic glass bottles debagger

DBMAutomatic debaggers for glass bottles. Designed to work in multi-format lines, there is no need to do adjustments or setting changes in the control panel when doing a change-over.

It is appropriate to be installed in clean areas (pharmaceutical industry).

Launching table into filling line

MLThe launching tables offer a semi-automatic solution for low production rates. There are various models depending on bottle format and its packing.

Launching table with manual debagging + bottle orientation

MDMThe launching tables offer a semi-automatic solution for low production rates. There are various models depending on bottle format and its packing.

Including a bottle orientation system.

Downloadable content

The content is restricted, in order to have access it is necessary to register

SOLUTIONS FOR THE INDUSTRIAL AUTOMATION OF PROCESSES

Bottle carriers | Milling systems | Leak testers for empty bottles | packers | Automatic bagging machine | Palletizing Robots | Pallets labellers | Automatic guided vehicles | Manufacture of masks