Industry 4.0

REMOTE SERVICES

From AND&OR we continue forward with our Industry 4.0 strategy, always adapting to our customer’s needs and to our industries evolution.

Our mission is to offer solutions and services for your factory to be efficient and connected.

With a good remote support, right documentation, and a full machine pre-test at our site, many of our machines (compact models) can be started up by our customers successfully, with no need of a specialist on site.

For this reason, we offer the Remote Service “Install yourself”

- It includes a modem that allows the Access to the PLC remotely, safe, and fast.

- It includes a pack of hours (depending on machine/project). You will have a direct connection with a technician exclusively for you, we offer this service in multiple languages

IoT – Monitoring

Motive

AND&OR, as an engineering machinery manufacturer with more than 30 years of experience, took each step since its inception focused on growing together with its customers, identifying their needs and offering solutions that provide added and differential value in the market.

In the current context of digitization, to increase the production processes efficiency and competitive advantage, AND&OR offers its clients the AO – IoT solution, on which it will present the different tools associated with INDUSTRY 4.0, for our customers to increase their production lines efficiency, resulting in better economic results.

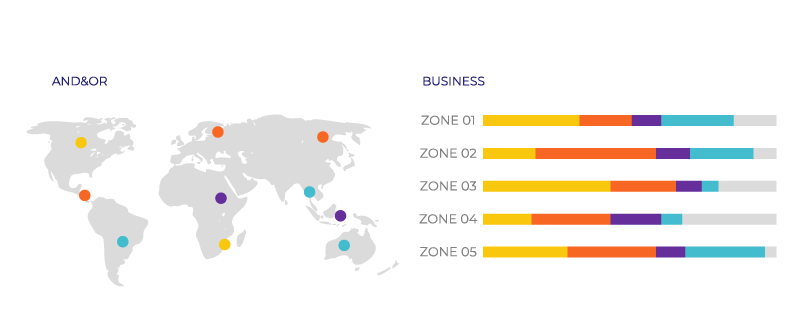

Reach

The great advantage of the platform INDUSTRY 4.0 – Monitoring offered by AND&OR is the connection with each machine forming the production network of your company, regardless of the communication protocol used, allowing to capture, process and present all the relevant information of your production and access in a simple and robust way until the last detail of the installation.

This versatility allows us to communicate with the main next generation industrial communication standards and protocols, providing universal connectivity and great compatibility with future evolutions thanks to the scalability of our platform.

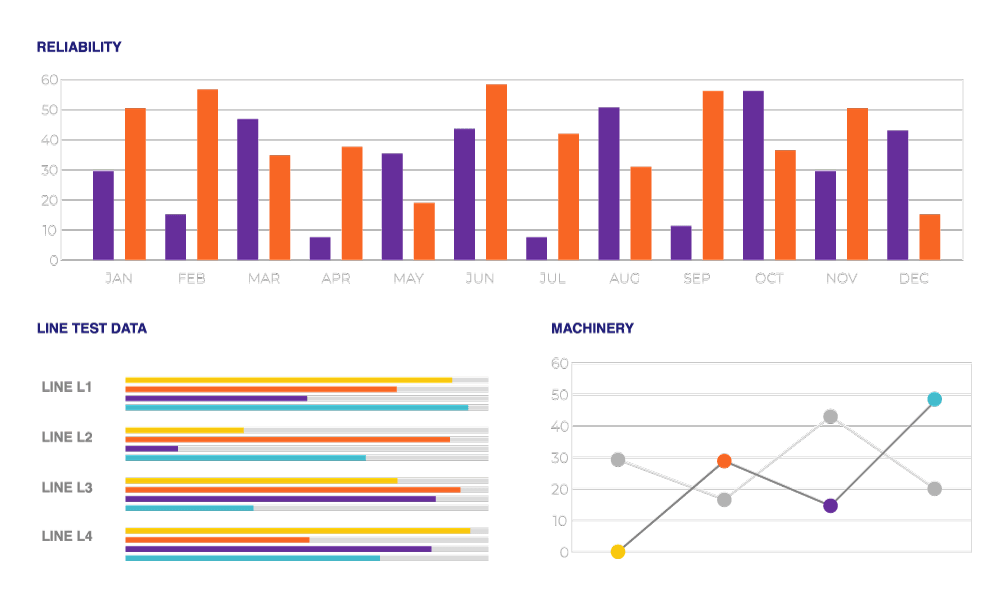

The platform is delivered on an industrial PC, including everything that is necessary to receive

reliable and relevant data in real time, as well as correct monitoring of production variables and analysis through a series of dashboards and KPIs.

Target

The AO – IoT solution is focused both on companies that already have a platform to manage their production and want to expand its scope, and those that want to monitor and optimize a specific production process or are taking their first steps in the digitization of their activities.

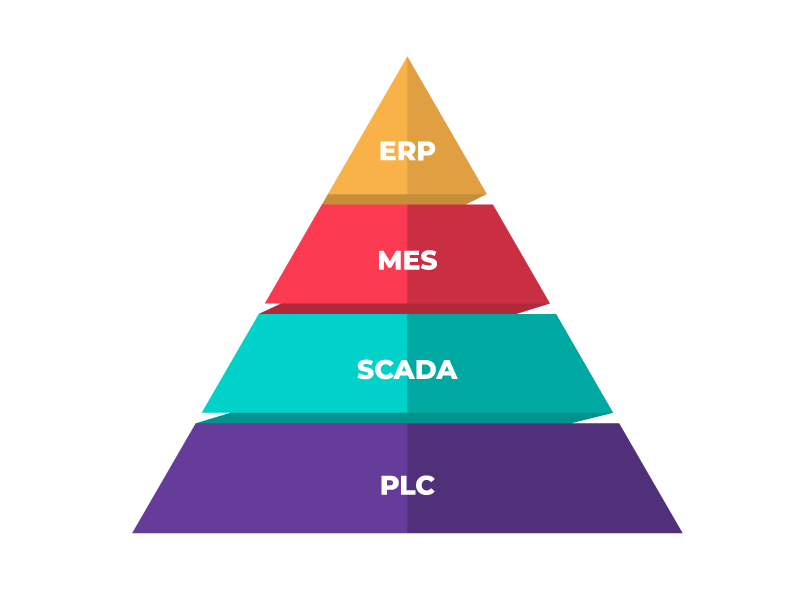

AND&OR is committed to Lean Manufacturing management models, which allow connecting the control and monitoring of production with the MES and ERP management systems of the plant.

Information management

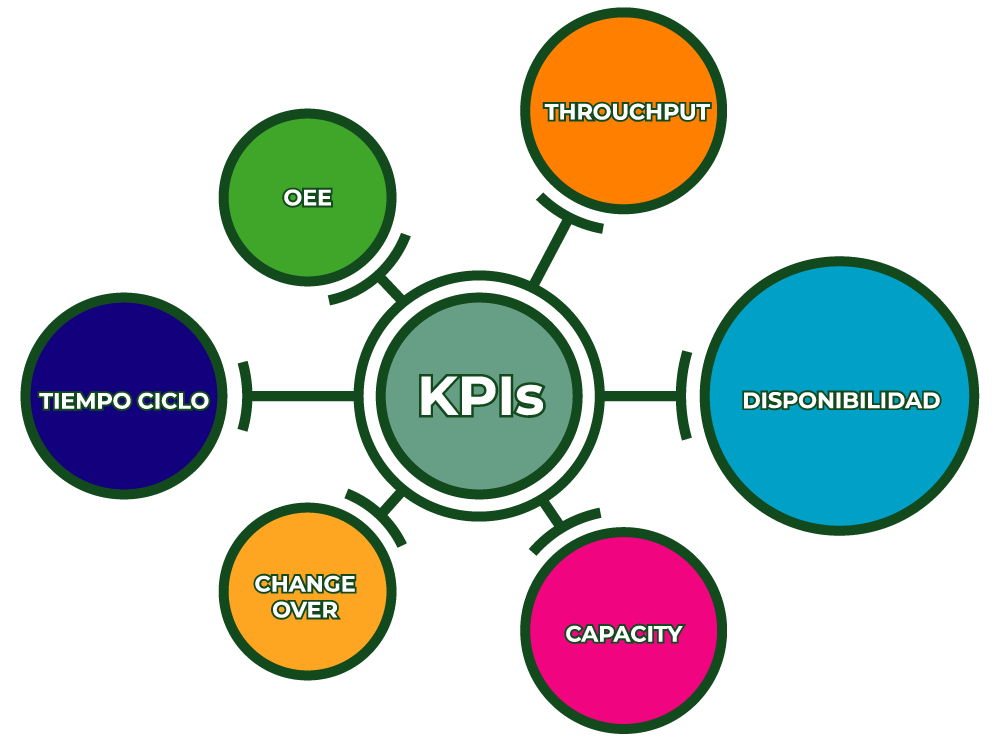

Monitoring – Dashboards and KPIs

For the monitoring and production analysis, the platform presents a series of dashboards with a multi-device visualization standing out by its friendly design, being accessible from a computer monitor, tablet, mobile phone or even Smart-TV with browser.

The focus in choosing these indicators is the supervision and production control: performance analysis (OEE calculation in real time), machine stops, rejected products, losses and inefficiencies, trend control …

Obtaining these indicators will allow the statistical analysis of the production process, viewing the results through control dashboards available to our customers.

Reporting

Our AO – IoT solution supports the periodic generation of custom-made reports with customized graphs for each customer that, together with an e-mail and sms alarm system, allow easy management and monitoring of activity in their facilities.

Custom-made solution

The architecture of our platform is adapted to our customers’ needs, allowing its customization to present the most optimal solution from the initial design stage.

Both the established KPIs and the reporting system are decided together with the customer in order to address the greatest possible casuistry and optimize their production control and monitoring system, working at the forefront of Industry 4.0, which will turn into in an economic improvement of their results.