Quality control and inspection

Regarding quality control and inspection systems, AND&OR can offer a wide range of equipment thanks to its long experience in leak control,, for both blow molding and bottling production lines.

Our models process from 1,000 up to 48,000 bottles per hours (bph) controlling containers from 150 ml to 20 L.

Due to the great versatility of the equipment and its automatic calibration, AND&OR systems are today a reference in the market.

Leak testers for empty bottles

(pressure decay):

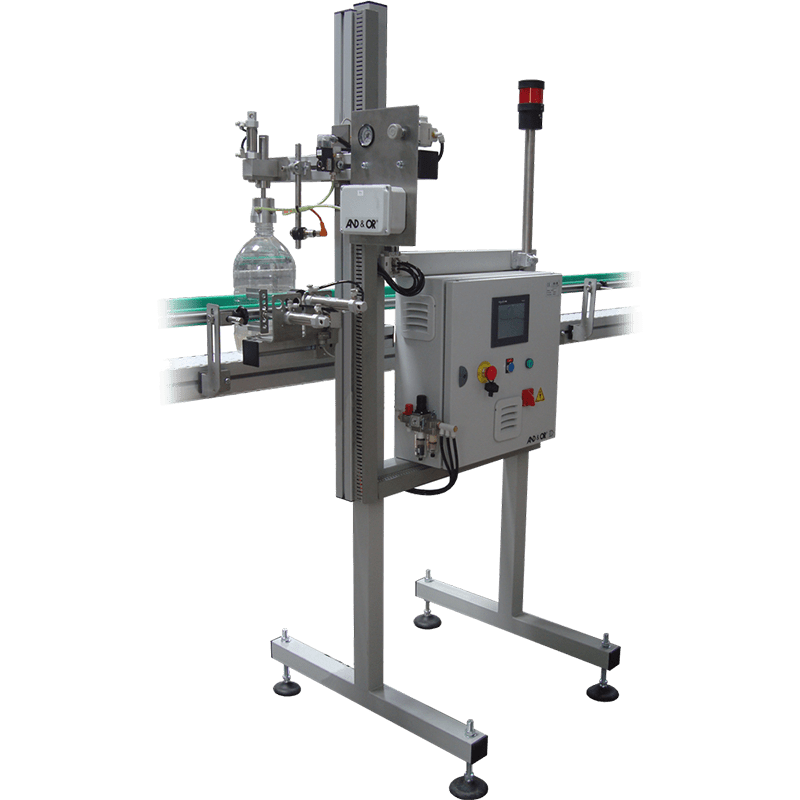

The linear leak testers are arranged in line over container’s conveyor can. They can be fitted with one or more heads, fixed or mobile, depending on the production required and bottle size.

Optionally weight control or camera vision systems are integrated in the leak tester machine.

| Up to… Bottle Per Hour (BPH) | 1000 | 2000 | 3000 | 4000 | 6000 |

| Linear without structure | LS1K | LS5K | LS8K | ||

| Linear with fix heads | LS1E | LS2E | LS4E | LS6E | LS8E |

| Linear with mobile heads | LS1-C1 | LS2-C1C2 |

* Production reference for 1L bottle – To check other volumes, please contact AND&OR.

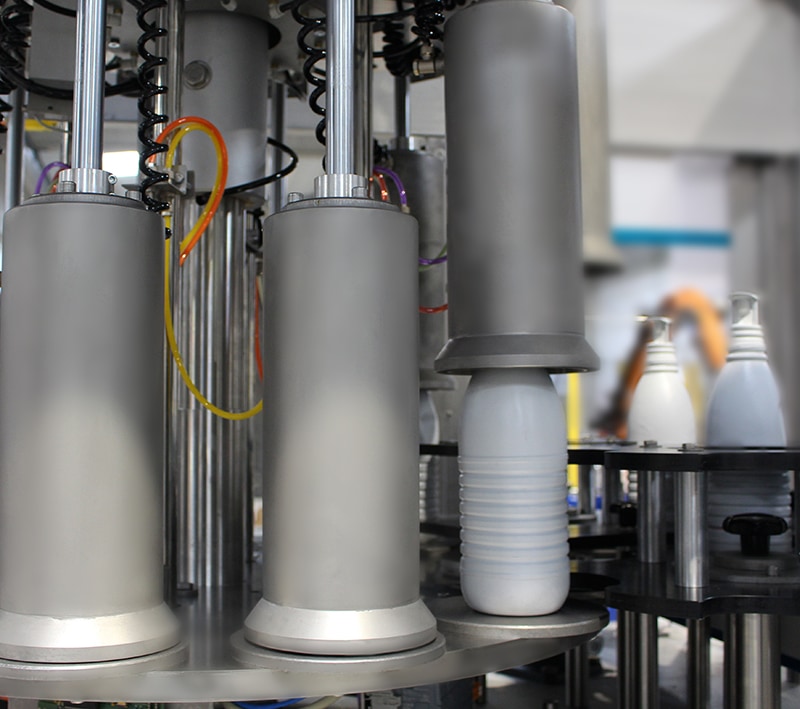

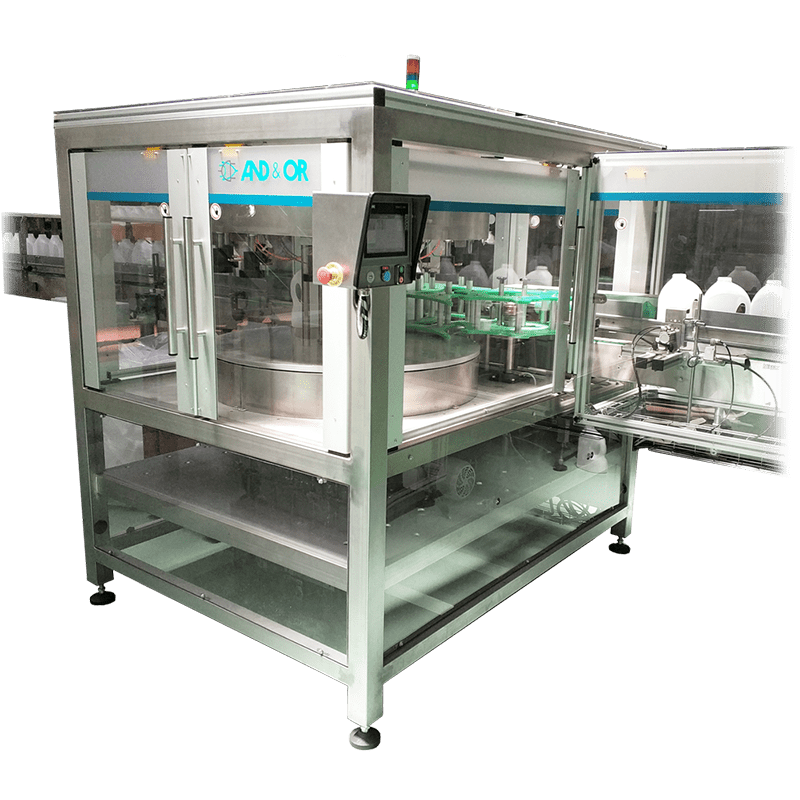

The rotary leak testers are generally set up in high production lines. Its simple, strong and high electronic technology design, make it very trustworthy, sensitive and precise, allowing productions rate up to 48,000 bph.

These leak testers machines can be equipped with extra features:

Leak testers for

filled bottles:

The leak tester for filled bottles works by applying lateral pressure on the bottle as it passes through the machine, calculating the corresponding pressure gradient.

Leak tester for closed bottles (vacuum decay):

This system makes leak control on closed bottles through vacuum decay test.

Product closure inside a hermetically sealed chamber on which the vacuum is created.

Capacities:

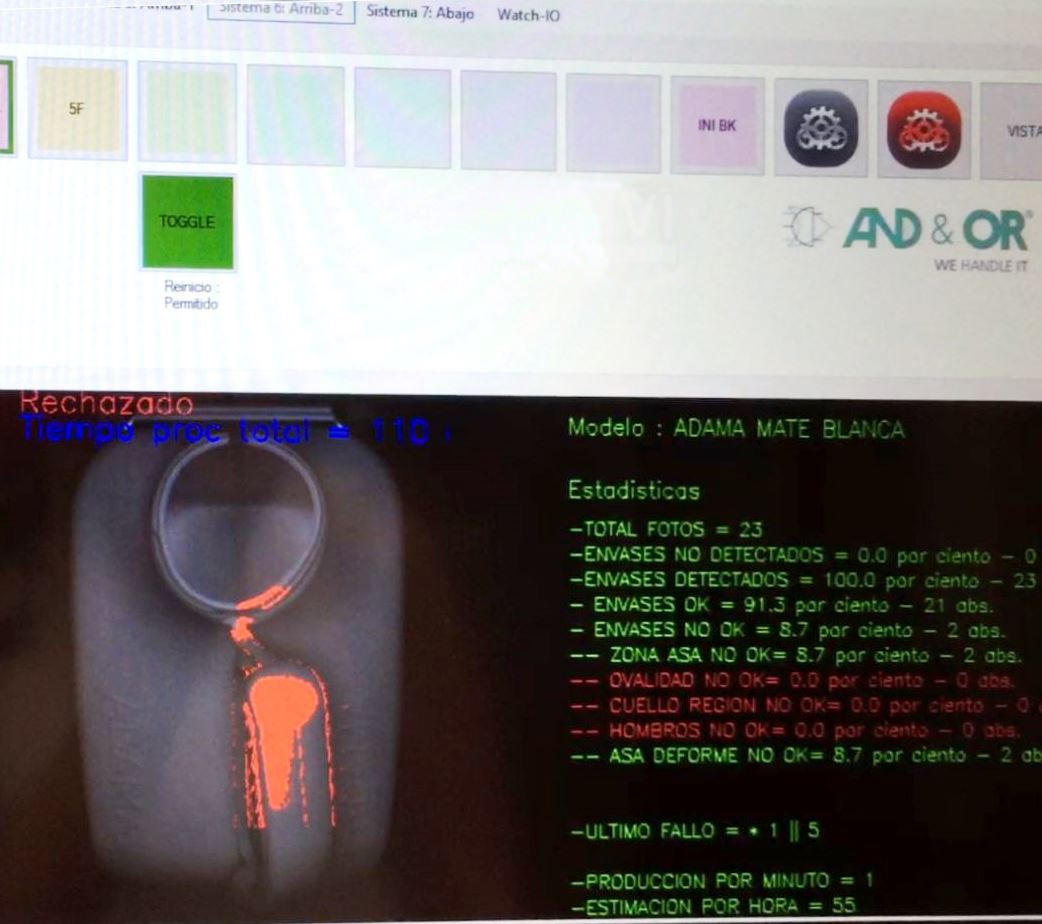

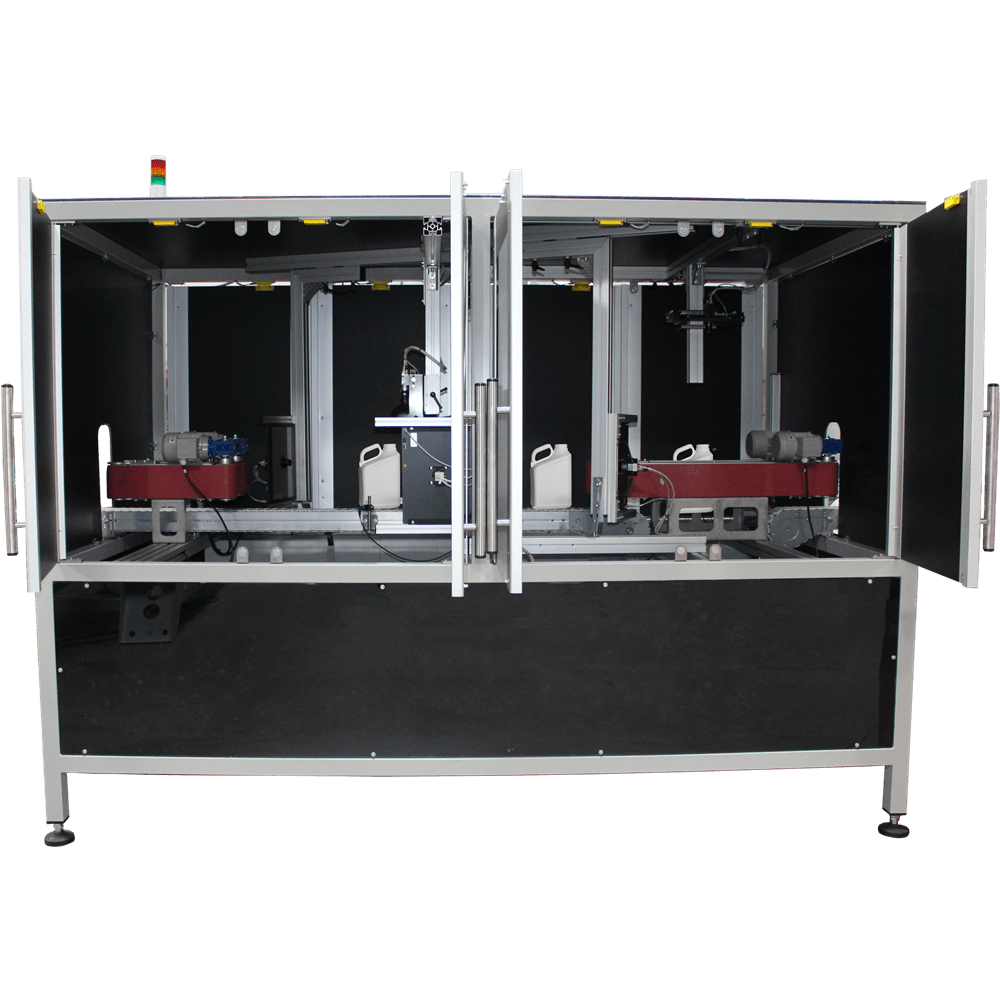

Artificial vision systems

360º artificial vision system guarantee the defects detection in plastic bottles, taps, handles and others.

The strictly studied optical design guarantees an optimum image quality with high quality and strength components, in an industrial environment condition, high speeds, and variable lighting and temperature conditions.

The artificial vision system can be integrated in leak testers, both linear and rotary.

Defects detected by artificial vision systems

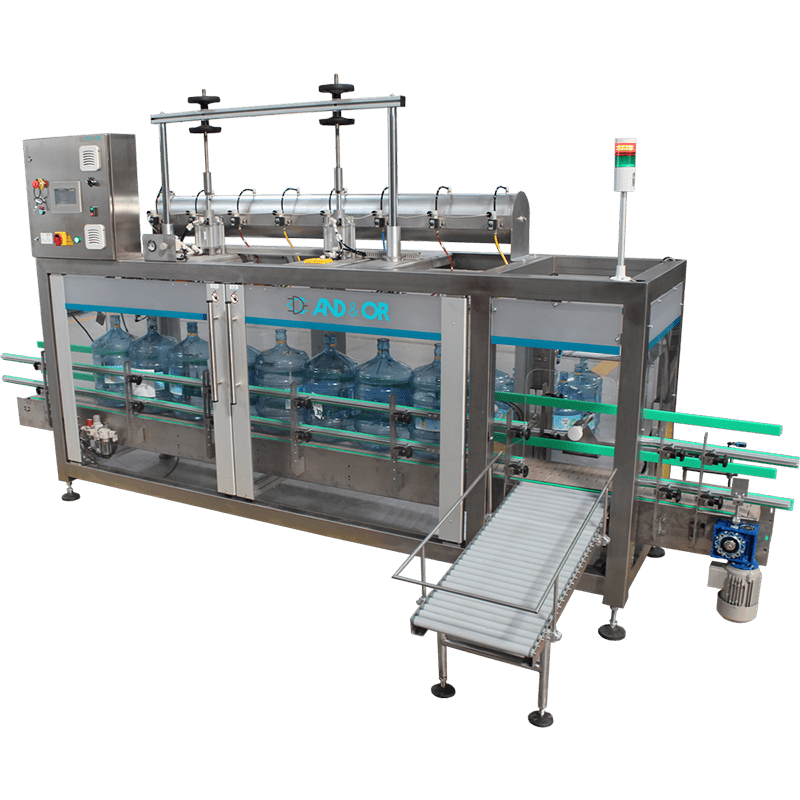

Leak and crack testers for 5 gallons containers (20l):

In case of large returnable containers (PET, PC), the machine is usually installed at the beginning of the line, after uncapping and previous washing.

Box weight tester:

AND&OR box weight tester is appropriate to be installed at the end of the filling line, after the wrap-around machine or box packer.

It detects if there is any bottle missing inside the packed box, as well as if there is liquid missing in any bottle.

Why choosing our system?

Why choosing And&Or?

These systems can be equipped with extra control features:

QUALITY CONTROL MACHINES

Linear leak Tester, without structure. Production rate: 1,000 BPH

LS1KLeak tester LS1K performs the control of plastic bottle’s leakages and avoids sending bottles with pinholes to the filling line. It is appropriate to be installed after the blower in blow molding lines, or before the filler in case of filling lines.

This leak tester, with 1 fix head, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 1,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

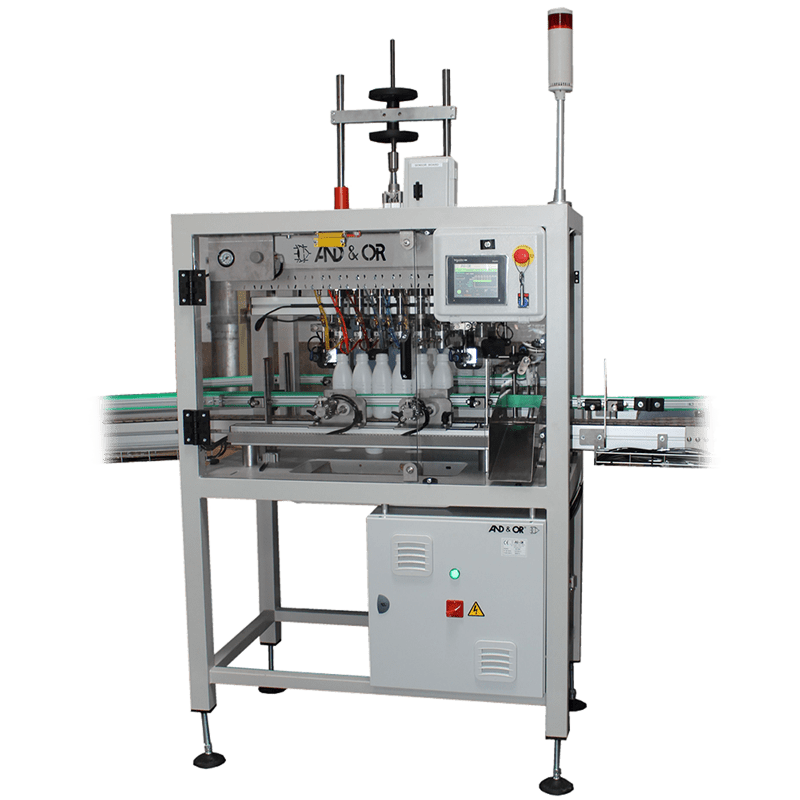

Linear leak Tester, with fix head. Production rate: 1,000 BPH

LS1ELeak tester LS1E performs the control of plastic bottle’s leakages and avoids sending bottles with pinholes to the filling line. It is appropriate to be installed after the blower in blow molding lines, or before the filler in case of filling lines.

This leak tester, with 1 fix head, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 1,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

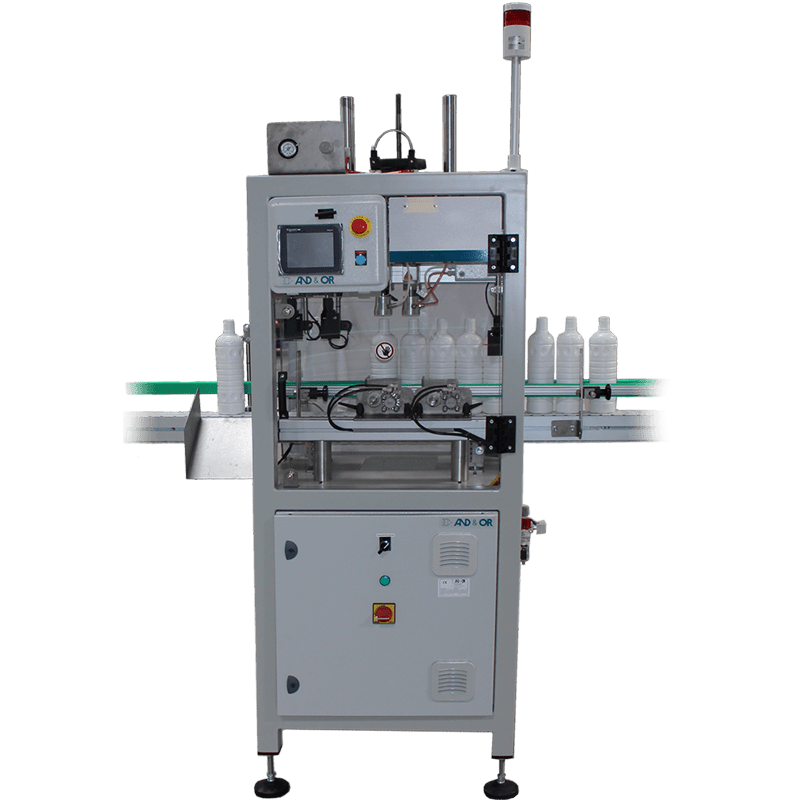

Linear leak Tester, with fix heads. Production rate: 2,000 BPH

LS2EThis leak tester, with 2 fix heads, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 2,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Linear leak Tester, with fix heads. Production rate: 3,000 BPH

LS4EThis leak tester, with 4 fix heads, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 3,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Linear leak Tester, with fix heads. Production rate: 4,000 BPH

LS6EThis leak tester, with 6 fix heads, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 4,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

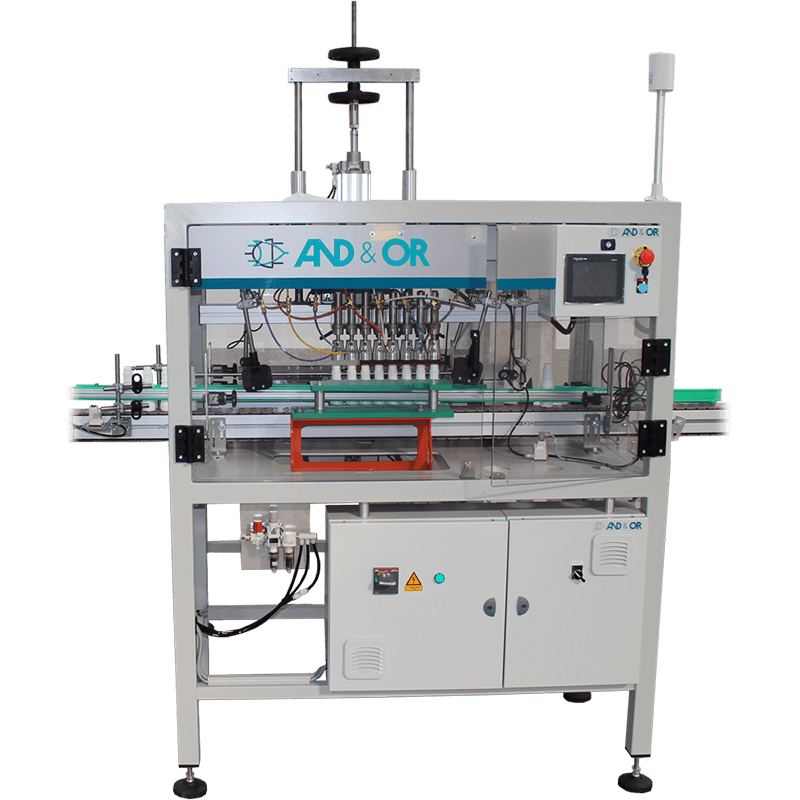

Linear leak Tester, with fix heads. Production rate: 6,000 BPH

LS8EThis leak tester, with 8 fix heads, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 6,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Linear leak Tester, with mobile heads. Production rate: 2,500 BPH

LS1-C1Leak tester LS1-C1 performs the control of plastic bottle’s leakages and avoids sending bottles with pinholes to the filling line. It is appropriate to be installed after the blower in blow molding lines, or before the filler in case of filling lines.

This leak tester, with 1mobile head, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole. It is recommended to be used in lines where bottles cannot be accumulated over the conveyor.

Maximum production rate: 2,500 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Linear leak Tester, with mobile heads Production rate: 4,000 BPH

LS2-C2Leak tester LS1-C1C2performs the control of plastic bottle’s leakages and avoids sending bottles with pinholes to the filling line. It is appropriate to be installed after the blower in blow molding lines, or before the filler in case of filling lines.

This leak tester, with 2mobile heads, allows keeping an adequate test time, guaranteeing sensibilities of 0.1mm diameter hole. It is recommended to be used in lines where bottles cannot be accumulated over the conveyor.

Maximum production rate: 4,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Rotary leak Tester, Production rate: 8,000 BPH

LSR8This leak tester, with 8 heads, allows keeping an adequate test time even at high speeds, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 8,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Rotary leak Tester, Production rate: 12,000 BPH

LSR12This leak tester, with 12 heads, allows keeping an adequate test time even at high speeds, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 12,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

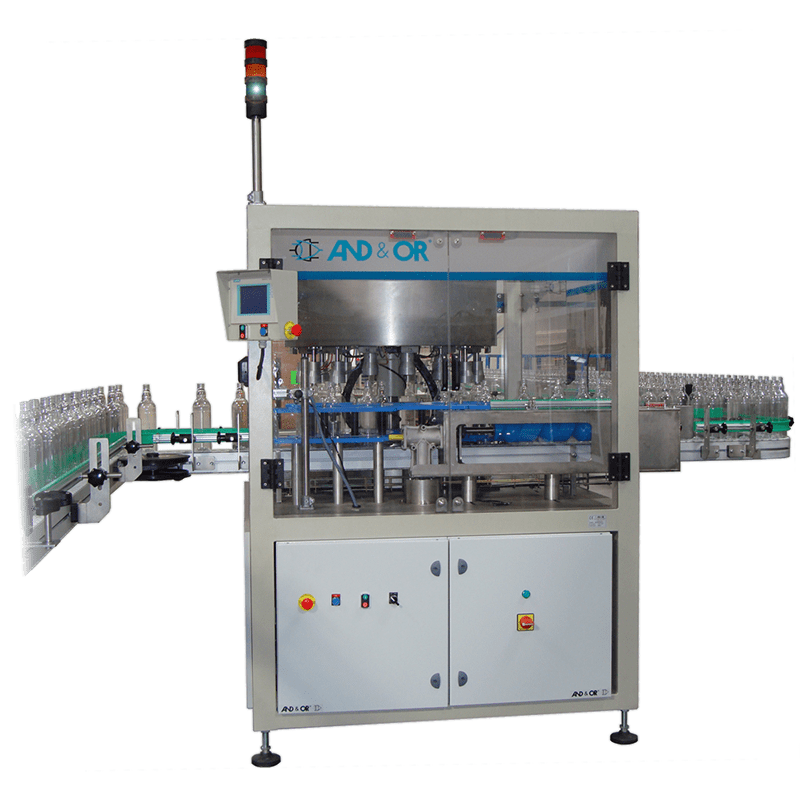

Rotary leak Tester, Production rate: 16,000 BPH

LSR16Leak tester LSR16 performs the control of plastic bottle’s leakages and avoids sending bottles with pinholes to the filling line. It is appropriate to be installed after the blower in blow molding lines, or before the filler in case of filling lines.

This leak tester, with 16 heads, allows keeping an adequate test time even at high speeds, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 16,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Rotary leak Tester, Production rate: 24,000 BPH

LSR24This leak tester, with 24 heads, allows keeping an adequate test time even at high speeds, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 24,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Rotary leak Tester, Production rate: 32,000 BPH

LSR32This leak tester, with 32 heads, allows keeping an adequate test time even at high speeds, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 32,000 BPH

*Production reference for 1L bottle. To check other volumes/speeds, please contact AND&OR.

Rotary leak Tester, Production rate: 48,000 BPH

LSR48Leak tester LSR48 performs the control of plastic bottle’s leakages and avoids sending bottles with pinholes to the filling line. It is appropriate to be installed after the blower in blow molding lines, or before the filler in case of filling lines.

This leak tester, with 48 heads, allows keeping an adequate test time even at high speeds, guaranteeing sensibilities of 0.1mm diameter hole.

Maximum production rate: 55,000 BPH

*Production reference variable depending on bottle format. To check other volumes/speeds, please contact AND&OR.

Box weight tester

CPL1It is appropriate to be installed in the packaging line after the wrap around/box maker machine. It has an electronic system based on a microprocessor and its versatility allows changing the production rate and modifying the weighting parameters.

(Capacity, division, etc.).

Leak tester for closed bottles

VLS-ROur system VLS-R makes leak control on closed bottles/packaging through pressure decay test.

Its simple, strong and high technology design make it highly reliable, sensitive and precise for productions from 6.000 until 24.000 bph (depending on model and headstock numbers of rotary system).

It is an automatic rotary machine, with electronic equipment based on micro-processor AND&OR. The test is made in a bell closing hermetically, inside there are the closed bottles (full or empty), then the emptiness is made, and the evolution of pressure is calculated during a given period of time. Rejecting the bottles/packaging with a leakage at its output.

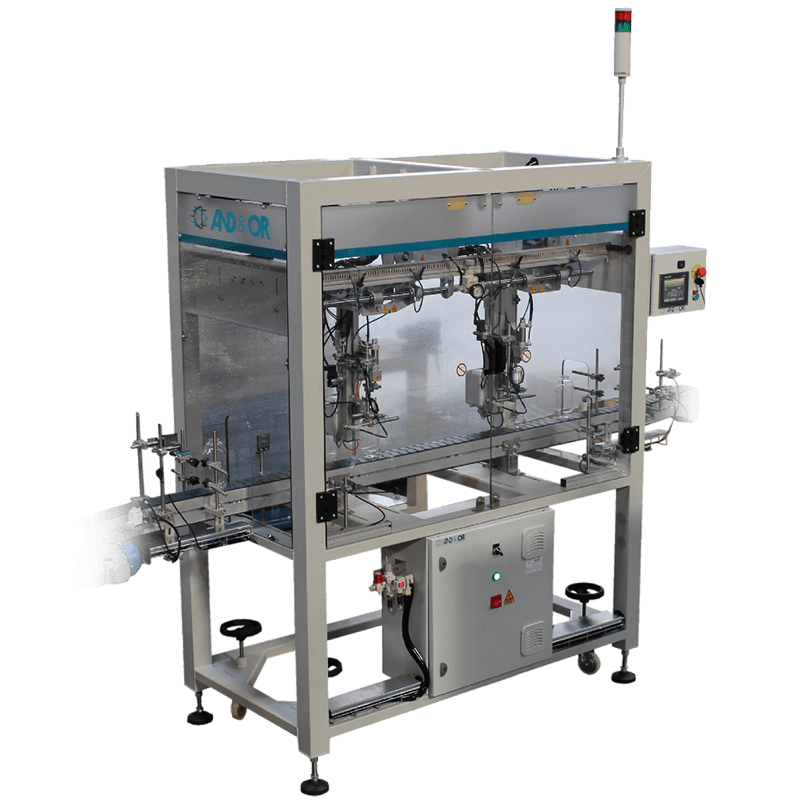

Leak and crack testers for 5 gallons containers

LSE-GILeak tester LS2E-GI performs the control of 5 Gallons plastic bottles leakages and cracks, and avoids sending bottles with holes to the filling line. It is appropriate to be installed at the beginning of the filling line, after uncapping and previous washing.

Production rate: from 1,000 to 2,500BPH

Available with 2, 4, 6 or 8 headstocks

Leak and weight tester

LWSLeak and weight tester LSW is based on a combination of linear leak and linear weight machine. Its microprocessor technology provides a wide range of functions, such as: weighting bottles and detecting micro-leaks at desired sensitivity. The system is fully automatic, simplifying its use and maintenance.

Maximum production rate: depending on model/bottle

360º artificial vision system

VA360º artificial vision system guarantee plastic bottles, taps, plastic handles and other defects detection.

It detects, among others:

- Circularity

- Black dots

- Breaks

- Inside/neck flashes

- Horizontal/vertical flashes

- Lack of material

The strictly studied optical design guarantees an optimum image quality with high quality and strength components, in an industrial environment condition, high speeds, and variable lighting and temperature conditions

- Flexible application

- Easy configuration

- Up to 6 inspection tools

- Different defects types.

- Inspection of various specific areas of bottles.

Downloadable content

The content is restricted, in order to have access it is necessary to register