A machine developed for the PPE production, FFP2 and FFP3 has

been added to the solutions line offered by the Spanish group AND & OR for the

health industry.

Production PPEs- FFP2 FFP3

In the guides that the Spanish Ministry of Industry, Trade and Tourism publishes on its website, one can find those that refer to the regular manufacturing process for PPE masks and how to legalize them.

What are the Personal protective equipment PPE

We understand PPE as a product intended to be worn by a person in order to protect against any health risk.

PPE masks are intended to filter the inhaled air, preventing the entry of polluting particles into the body.

PPE protective equipment personnel must be CE marked in accordance with regulations of the European Union on 2016/425 personal protective equipment, which explains what PPE is as well as the conditions to be fulfilled and the processes to be followed by manufacturers to market it.

Can masks be considered PPE?

Masks intended to protect those who wear them against the inhalation of hazardous substances are PPE and are therefore required to comply with EU-2016/425 regulation.

As is known, there are other types of masks which are not PPE such as surgical masks which are medical devices and which must comply with Directive 423/92 / EEC.

Existing types of PPE masks

In annex II on the essential health and safety requirements that PPE must meet, and which is included in regulation EU-2016/425, there is a standard EN 149: 2001 + A1: 2009 in which are defined the different types of protective masks against particles that can:

Depending on their performance and their maximum total internal leakage, there are three classes of devices:

FFP1, FFP2 and FFP3

For protection against COVID-19, the use of PPE FFP2 masks is recommended.

Whatever the material used for their manufacture and according to the results obtained in the tests carried out, they are classified into 3 groups:

masks Low efficiency FFP1: filtering at least 80% of aerosols (total inward leakage <22%)

Medium performance FFP2 masks: filtering at least 94% of aerosols (total inward leakage <8%)

High efficiency FFP3 masks: filtering at least 99% of aerosols (total inward leakage <2%).

Production process of PPEs- FFP2 FFP3

Before starting the production process of PPE masks of type FFP1 and FFP2, the regulations in this regard must be known:

- UNE-EN 149: 2001 + A1

- Regulation (EU) 2016/425

In these regulations there are no specific obligations regarding the method of manufacture, nor the machines, nor the type of fabric, but certain necessary requirements are included.

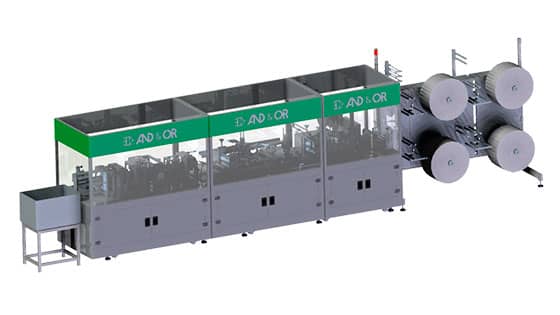

AND & OR group developed a machine to manufacture masks with a capacity up to 80/min. Self-filtering masks FFP2 and FFP3 according to current regulation.

A summary of the manufacturing process of FFP2 / FFP3 masks would be as follows:

For the manufacturing process of FFP1 and FFP2 masks, have a warehouse or premises of at least 500 m2 and have a specialized automatic machine for manufacturing masks PPE or a fabric cutting machine and a folder to shape the masks.

Once the shape of the mask is completed, it is finished with seams and elastics for attachment.

Regarding the materials for manufacturing, manufacturers generally use: Meltblown and Spunbond, two polypropylene non-woven, both sold by AND & OR. Moreover, the ear loops and aluminium nasal rigid strip will be required.

Any mask must adapt perfectly to the user’s face and prevent the entry of particles through its outline.

In the nasal area, the mask may have a metal band, normally aluminum, on the inside to allow the mask to adjust to the shape of the user’s nose. The rubber straps should allow the adjustment of the head.

The company that manufactures the FFP2 / FFP3 masks will be responsible for marking the product with the CE mark and its packaging and is responsible for ensuring that the mask has been manufactured in accordance with regulations. To do this, it must prepare technical documentation. and a conformity assessment procedure, referring a notified body to perform the tests set by the standard for the manufacture of FFP1, FFP2 or FFP3 masks.

PRODUCTION, HANDLING AND MATERIAL FOR MASKS

Face masks production machinery | FFP2 and FFP3 masks |

Peripherals and packing solutions | Materials for mask manufacturing

All the information published in this content has been taken from the guides published on its website by the Spanish Ministry of Industry, Trade and Tourism:

- Regular production of masks, in the EPI team, edited by the General Secretariat of Industry and Small and Medium Enterprises.

- CE marking of filtering masks for protection against particles (Personal Protective Equipment, PPE)

In view of the variations and constant updating of regulations and directives, we recommend at all times to consult the official sources of the Ministry of Industry of your country as well as the regulations in force at all times.

Leave A Comment